- The PERC+ bifacial cells from ISFH attained a bifaciality factor of 80% with 20.9% front efficiency

- Developments in metallization pastes and improvements in interconnection are key enablers of the approach

- ISFH’s bifacial cells are processed without adding new steps to PERC process flow

- Aluminum is used for rear finger grid, making these bifacial cells most cost competitive over the other well known approaches

- The PERC+ cells exhibited better front side efficiency over monofacial cells due to better rear contact formation and deeper BSF

A good timing to introduce a technology is very important from a commercial point of view, but sometimes it takes time until other technologies and materials are ready to go as well. Adapting the bifacial concept to PERC cell technology is an example, where the right time has come.

While the approach was evaluated by several others in the past without success, the Institute for Solar Energy Research Hameln (ISFH) has presented very encouraging first results at the last European Photovoltaic Solar Energy Conference (EU PVSEC). More than the bifacial approach, what essentially has made the concept work this time are improvements in other areas. The PV division head at ISFH and inventor of the concept, Thorsten Dullweber, credits this success to the improvements in paste and interconnection rather than developments in bifacial technology.

Bifacial PERC: 20.9% front, 16.7% back

The beauty of ISFH’s bifacial technology adapted to PERC architecture, named as PERC+, is that no additional process steps are added to the typical PERC process sequence. That means, only through optimization, ISFH successfully transformed PERC into a bifacial cell, attaining efficiencies of 20.9% on the front and 16.7% on the rear side. Then, the bifacial PERC concept is not something incubated in research labs. “The technology is industrially viable,” emphasizes Dullweber.

Another proof is SolarWorld’s move into bifacial products. Independent from the research at ISFH, the German vertically-integrated PV manufacturer developed a very similar technology and transferred it into production. In March, SolarWorld, announced that its US factory produced its first bifacial Bisun modules for installation in a 205 kW system at the University of Richmond, Virginia. And Dullweber’s presentation at PVSEC also included the synopsis of Solar World’s foray into commercialization of the technology. SolarWorld had already launched glass-glass bifacial PERC module at the last Intersolar Europe trade fair in Munich, Germany.

Prior art

PERC architecture is currently the hot topic of the PV industry (see our new free report ‘PERC Solar Cell Technology 2016’). An increasing number of cell makers is pursuing the technology – in our report, we estimate that 4.9 GW PERC capacity was installed in 2015, this year it will be 11.8 GW. Th PERC cell concept adds a passivation layer on the rear side, but the application for aluminum on the full area of the back side remains the same. This metallic film, serving as rear contact, is opaque and stops any sunlight entering the solar cell from the rear side.

In parallel to PERC, the bifacial approach, making solar cells light sensitive on both sides, is also gaining popularity. The important attribute of the bifacial concept is that it can be adapted to any cell architecture – and the most common ones are Passivated Emitter and Rear Totally diffused (PERT) and heterojunction cells. Both structures usually employ n-type wafers as base. Apart from the fact that these technologies are still niche products, silver contacts are screen printed on both sides of the wafer, which simply doubles silver consumption per cell. On top, the PERT process involves phosphorus diffusion to establishing a back surface field (BSF), in addition to the formation of an emitter with boron doping. That’s not just one more process, but the additional BSF forming step adds ancillary masking and cleaning processes.

Earlier attempts to combine PERC & bifacial

Thus, the most logical combination would be PERC and bifacial technologies. The first step towards that is to replace the full area aluminum with a finger grid like on the front side, but using aluminum paste, instead of silver. That doesn’t seem a very difficult task to execute these days. And here ISFH shows the right timing. Works on similar grounds by other research groups in past were simply not fruitful. Back in 2001, ISFH itself evaluated a bifacial structure on a p-type cell, which on the rear side printed H-pattern aluminum contacts fired through the SiNX rear passivation layer. The approach avoids the laser contact opening step of the typical PERC process. Dutch research center ECN further developed this approach, called p-PASHA. ECN even evaluated using uncapped aluminum oxide deposited with ALD as rear passivation material. However, the resulting efficiencies were similar to standard Al-BSF cells and lower compared to industrial PERC cells. Germany’s RCT Solutions reported a bifacial PERC cell on a p-type multicrystalline wafer with a front side efficiency of 18.4%. However, the company employed an additional step of boron diffusion to realize the BSF.

Going PERC+

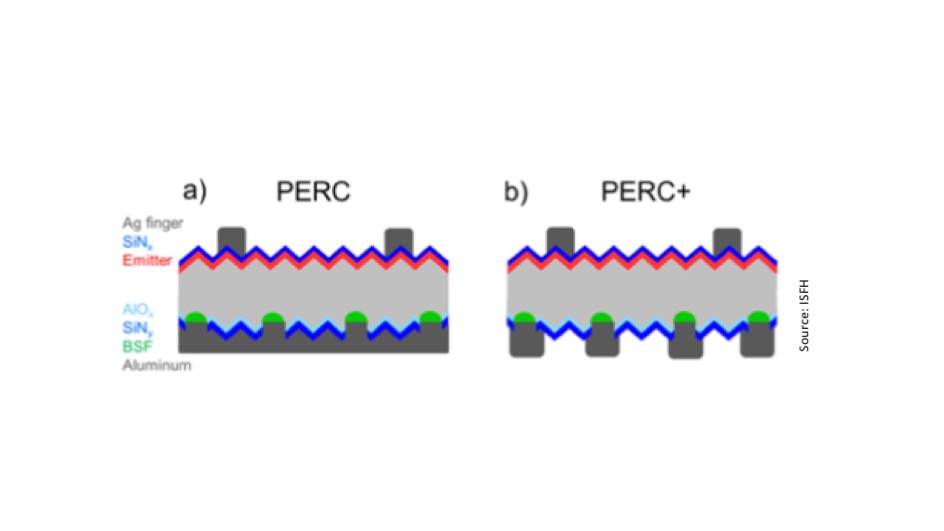

The significance improvement of the PERC+ process developed by ISFH is that it does not add any additional step. It is based on a typical industrial PERC process flow, consisting of an aluminum oxide and silicon nitride rear passivation stack, which is opened with a laser for contact forming.

A slight change is that the aluminum finger grid is screen printed on the rear side instead of application on full area. A little bit of extra care has to be taken to align contacts to the laser openings. This change in rear metallization pattern clearly increases the grid line resistance, because the current now has to flow through narrow fingers. On top, the conductivity of screen printed aluminum fingers is rather bad, around “6 to 7 times lower than screen printed silver”, adds Dullweber. It is also the same reason why earlier approaches failed – high resistance losses originating from the aluminum fingers.

Now what went in favor of ISFH, according to Dullweber are recent developments in the aluminum paste segment, among others. An even more important aspect is the five busbar design. This recent trend of increasing the number of busbars in the interconnection segment clearly reduces the resistance burden on the fingers – be it front or rear, silver or aluminum based. “More busbar designs are enablers of our concept,” says Dullweber, adding, “Because we are not being limited by the aluminum grid lines’ resistance.” But why not use silver to gain in conductivity? Apart from the “precious” part of the silver, it is simply not suitable, says Dullweber. Silver requires a highly doped surface, while the rear sides of typical PERC cells do not receive any active doping. Thus, regarding costs as well as technical reasons, an aluminum grid is ideally suited.

The PERC+ cell is more attractive than many other bifacial approaches, as the silver paste consumption, which tops the list of cell conversion costs, could be straight away reduced by half. Adding a feather to the cap, this process also reduces the aluminum paste consumption dramatically – from about 1.6 grams to 0.15 grams.

Making PERC bifacial

The PERC process, however, is not just a drop in replacement, and some process steps have to optimized. The thickness of the silicon nitride capping layer was set to 80 nm to ensure low reflective rear side, while the reference monofacial cell had a 200 nm capping layer thickness. As for laser opening, ISFH expressed the change only in relative terms – 1.5 times to what has been set for the standard PERC cell in order to reduce the rear metal coverage and shading losses. The width of laser openings are wider than the typical contact openings. The aluminum screen has a finger opening of 100 mm. On the front side, ISFH applied dual printing, applying low activity silver paste for busbars and fingers with stencil printing.

Almost no bowing

According to ISFH’s research paper, the aluminum metallic pattern occupied 14.2% of the rear surface, and, interestingly, almost now bowing was observed compared to standard PERC cells with a bowing spec of 2.5+/-0.5 mm. This is mainly because PERC+ cells are quite symmetric with both wafer surfaces being coated with dielectric layers and metal grid lines, hence reducing the mechanical stress within the wafers compared to PERC cells with the full-area aluminum layer on the back side. The researchers also observed that the aluminum finger grid contributes relatively little to the resistance because of the 5-busbar design. Another interesting aspect is that a better BSF could be realized with PERC+ cells due to the aluminum finger layout. The study shows that while the bifacial PERC+ cell exhibits Al-BSF depths of 5.5±1.5 μm, monofacial reference cells only realized 3.5±1.5 μm deep, which increases the Voc by 3 mV.

Explanation for much lower rear-side efficiency

Overall, the fully processed PERC+ bifacial cells resulted in a front side efficiency of 20.9% and a rear side efficiency of 16.7%, corresponding to a bifaciality factor of 80%. This low rear side performance is attributed to the low short circuit current density of 31.8 mA/cm2, which is about 8.1 mA/cm2 less over the front side. ISFH’s research group has investigated the root cause, which was found to be a significantly higher reflectance on the rear side. On the other hand, bifaciality is not the lone beneficial parameter, according to Dullweber. He points out to the fact the best front side efficiency attained by PERC+ cells, which was 21.5%, is higher than that of the 20.9% obtained for the reference monofacial cell during the research work. While ideally they should be the same, according to Dullweber, the acclaimed advantage is due to the fact that the aluminum finger grid results in improved contact quality over the full area aluminum and the process flow results in a deep BSF. He emphasizes that the front side efficiencies of PERC+ cells are higher than n-PERT, the most common bifacial cell structure in these days, and rear side are bit lower.

All in all, the overall output of PERC+ is comparable to n-PERT cells, but ISFH’s production process is more simple and thus it should be also cheaper. While improvements in other segments – pastes and interconnection – have made the technology feasible, its widespread use essentially depends on yet another development – the success of glass-glass modules.