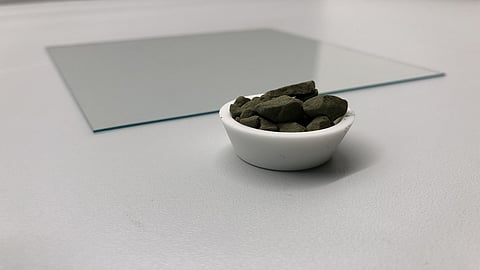

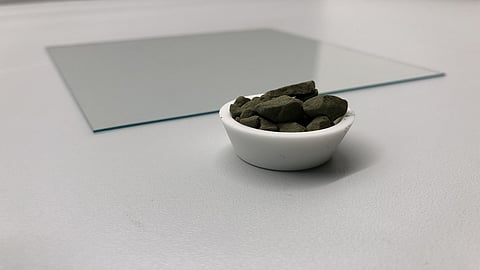

Germany's Karlsruhe Institute of Technology (KIT) has developed a 'novel, highly efficient' hole conductor layer for perovskite solar cells using nickel oxide (NiOx) to be deposited over a large area that it claims leads to record breaking efficiencies in these solar cells. Using the vacuum process technique of electron beam evaporation, the team was able to homogenously place metal oxide deposits on a substrate by means of vapor deposition over a large area.

The NiOx based layer is not only inexpensive but also less sensitive to temperatures of more than 70°C, claim the researchers.

For fully vacuum-processed perovskite solar cells, the team achieved efficiencies of up to 16.1%. In addition to this technique, the researchers deposited the absorber by inkjet printing which created a 'world record' with 18.5% efficiency level. "Currently, development is dominated by deposition by spin coating for which efficiencies of more than 24% have been achieved. However, these can practically not be transferred to large areas," said Tobias Abzieher a doctoral student at the Institute of Light Technology at KIT.

The team is working on scalable manufacturing processes to bring perovskite PV from the lab to the fab.

Their research is supported by the Federal Ministry of Education and Research (BMBF), the initiation and networking support of the Helmholtz Association and the Karlsruhe School of Optics & Photonics (KSOP).

.png?w=50&fm=png)