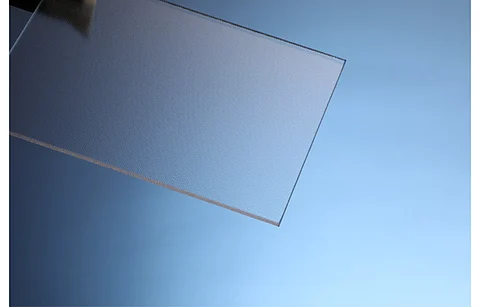

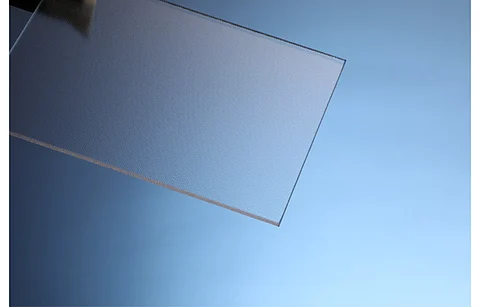

India headquartered solar glass manufacturer Borosil Renewables Ltd (BRL) has announced the launch of what it terms as the world's 1st antimony-free low-iron textured solar glass in the European market. It is produced by its subsidiary Interfloat Corporation in Germany.

BRL has already been producing this antimony-free glass NoSbEra in India, using a patented technology, for which it has a certification from Switzerland's Institut fur Solartechnik SPF. It claims SPF test results show that BRL's antimony-free glass has no photo-degradation and also has highest efficiency among solar glasses.

Now the manufacturer is expanding its customer base for this product to Europe. It will be manufactured at GMB Glasmanufaktur Brandenburg GmbH (GMB) fab in Brandenburg, Germany and sold by Interfloat. Later it plans to reach out to its global customer base for this glass product.

In October 2022, BRL acquired the largest European manufacturer of textured tempered solar glass, Interfloat Group that comprises GMB Glasmanufaktur GmbH with 300 tons/day capacity (see India PV News Snippets).

A heavy metal with symbol Sb, antimony is extensively used in the production of solar glass to help improve stability of the panels when exposed to ultraviolet rays of the sun. However, once the panel reaches end-of-life and is disposed unsafely, the metal can leach into the environment and cause health issues in humans ranging from skin and respiratory problems, gastro-intestinal functions and is possibly carcinogenic to humans.

Germany in its recent solar manufacturing tender asked for Sb-free glass, among other environmental boundary conditions, such as lead free cells and PFAS-free modules (see Germany Launches Big Solar PV Industry Tender).

BRL says the estimated cumulative solar glass waste by 2030 will be 1.5 to 1.7 million tons. Since the front glass of a single PV module uses about 32 to 48 gms of antimony, it would mean 3,000 tons to 20,000 tons of antimony as part of the waste by the end of this decade.

"We are looking forward to support our valuable customers to develop a truly sustainable and reliable supply chain of domestically manufactured high efficiency solar modules," said Executive Chairman of BRL, Pradeep Kheruka. "We believe this glass to be the best choice for those who wish to manufacture high performance and environmentally friendly solar panels."

Claiming to have one of the lowest carbon footprints in solar glass manufacturing globally, BRL has an integrated capacity of 1,000 tons/day in India which is equivalent to 6 GW, and 350 tons/day in Europe, representing 2 GW capacity.

The solar industry is increasingly becoming mindful of its carbon footprint and trying to mend its way right from the manufacturing stage itself right down to the recycling stage of panels, something we discussed with our panelists during our 1st Solar & Sustainability Conference in March 2023. Presentation links are available here.