JA Solar is one of the leading PV manufacturers that is seriously evaluating rectangular wafer sizes and working on optimized module sizes for various applications. The company launched a new module series called DeepBlue 4.0 Pro, which is based on a rectangular wafer size of 182 x 199 mm. Jerry Sun, senior manager of product promotion at JA Solar, shared the background and design intricacies of the DeepBlue 4.0 module series that is based on this somewhat atypical wafer size during the TaiyangNews Conference (see presentation here).

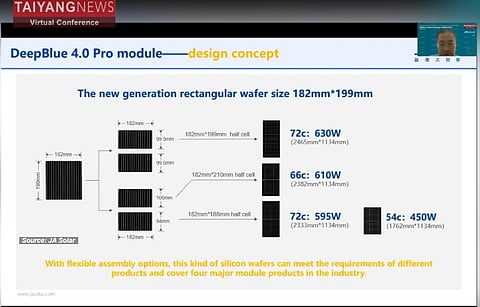

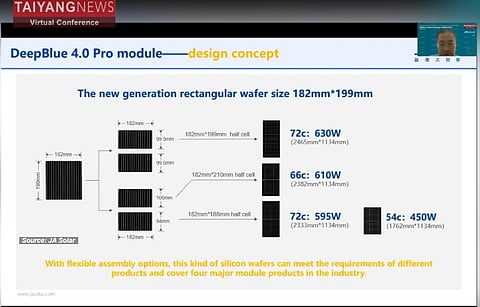

Reflecting on the current situation of the module sizes, Sun presented an overview of different module layouts, leading to different module dimensions, which can be realized with different wafer sizes. He noted that to cater to the industry mainstream 54, 66, 72, and 78 cell module layouts, at least 3 different wafer sizes are required. This puts strain on the supply chain of the entire industry and increases the non-technical costs of the end products. JA Solar tackled this issue smartly by using only one wafer size, i.e., 182 x 199 mm. The specialty of this wafer is that it can be cut in different ways to create modules of different sizes while maintaining the same module width of 1134 mm. For example, when the wafer is cut along the longer side, it can be used to create a 72-cell module with dimensions of 2465 x 1134 mm. When the same wafer is cut into 2 asymmetrical pieces of 105 mm and 94 mm, it can be used to create 66, 72, and 54 cell modules with dimensions of 2382 x 1134 mm, 2333 x 1134 mm, and 1762 x 1134 mm, respectively. In this way, JA Solar can create 4 variants of the DeepBlue 4.0 Pro modules from one wafer size, making them suitable for different applications such as utility, C&I, and rooftop. The use of a single wafer size for multiple module sizes has several benefits. It can help reduce the cost of the supply chain, improve equipment compatibility, and standardize module sizes. This can lead to lower integration costs and better system value, according to Sun.

However, the center of the production for the company was the 144 half-cell module measuring 2465 x 1134 mm with a power rating of 630 W and 22.5% efficiency. The module series features SMBB technology with more than 16 busbars. This improves light utilization and current collection, contributing to the efficiency improvements. High density encapsulation is yet another feature of this latest module series (JA solar DeepBle 4.0 modules stands at 7th position in TaiyangNews Top Solar Modules Listing).

In addition to the generic advantages of the TOPCon technology, including low temperature coefficient, high bifaciality, better low light response, and low degradation, the DeepBlue 4.0 Pro also comes with high reliability. The module series has passed all standard and enhanced reliability tests. Sun also presented the results of a field test conducted by JA Solar in cooperation with TUV Nord, which showed that the energy yield of the DeepBlue module based on n-type Bycium+ cells is close to 4% higher than the reference PERC products.

He also presented the comparison data of system calculations for different products, which showed that, depending on applications, project types, and installation methods, DeepBlue 4.0 Pro modules can help reduce BOS costs by 1.4% to 4.5% and LCOE by 0.7% to 6% over the comparable p-type modules. As part of the company's technology roadmap, Sun, in addition to presenting the expected progress of the TOPCon technology from the current level of 25.3% efficiency to 26% by 2025, also emphasized that the company will continue working on other technologies such as HJT, XBC, and perovskites based tandem structures.

The text is an excerpt from TaiyangNews New Solar Products Overview H1/2023, which can be downloaded for free here.