PV product designs are increasingly becoming application sensitive. Let alone optimizing the module size, even the cell technology has become application specific, at least for the world's largest PV manufacturer LONGi. It is well known that it launched the Hi-MO 6 series for residential applications at the end of 2022. The company has now chosen TOPCon as the cell architecture for its solutions targeted at utility applications, and has named the series as Hi-MO 7. Jason Yan, senior product marketing manager at LONGi, presented the details of the latest Hi-MO 7 solar modules at the TaiyangNews Virtual Conference on Global PV System Technology Trends H1/2023 under the title "Hi-MO 7 efficiency at its best for utility applications."

Tracing LONGi's legacy, Yan highlighted that the company has led the market in both wafer and module shipments from 2020, boasting 46.8 GW in modules and a whopping 85.1 GW in wafers in 2022. Not just in shipments, the company also set several records in cell efficiencies. LONGi still holds the record for the world's best crystalline silicon solar cell efficiency with its HJT cell of 26.81%. It also holds the title for the highest p-type HJT cell efficiency at 26.56%. Not just records, LONGi is also pursuing long-term product reliability. Yan emphasized that every innovation of LONGi has set a benchmark in the industry and helped accelerate the reduction in LCOE.

LONGi is currently promoting 3 product groups: the Hi-MO 5, known for its cost-efficiency and performance surpassing expectations; the aesthetically pleasing Hi-MO 6, tailored for the distributed market; and the Hi-MO 7, the n-type bifacial module designed for utility applications, especially with limited land, high albedo and higher temperatures such as deserts.

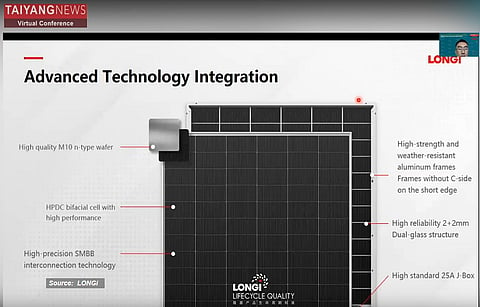

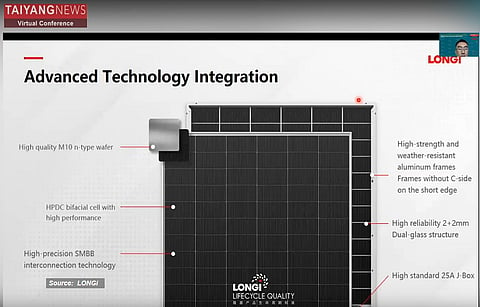

Delving into the specifics of Hi-MO 7, it's built on an M10 wafer size, boasts a 580 W power rating and 22.5% efficiency. It uses SMBB interconnection technology. This module is especially suitable for high albedo scenarios with its 80% bifaciality and better temperature coefficient of -0.28%/°C, which makes it more effective than PERC in such scenarios. The module is built with double-sided 2 mm glass, high strength and weather-resistant aluminum frames without C-side on the short edge and a 25 A junction box. Backing its commitment to quality, LONGi offers a product warranty with 0.8% as the first-year degradation and 0.38% thereafter, which is backed by LONGi's lifecycle quality system to ensure the module's reliability. Yan presented real-world scenarios in which HiMO 7 showed 2.9% power gain over mainstream products in Hainan, a high-temp and humid env with 27% albedo.

Regarding production, LONGi is ramping up, targeting a 30 GW capacity in 2023 with facilities in Ordos, Chuzhou, and Jiaxing. The Hi-MO 7 production is slated to kick off in July 2023. Yan also shed some light on LONGi's HJT technology that led to the record cell efficiency of 26.81%. The cell, based on 130 μm wafers, features doped nanocrystalline silicon oxide (nc-SiOx) layers on both sides. The TCO coatings are also optimized, especially on the rear side with hydrogen plasma treatment. All this led to an improvement in optical transmission and electrical properties with reduced contact resistance.

During Intersolar, on June 14, LONGi announced that it has achieved a conversion efficiency of 33.5% for its crystalline silicon-perovskite stacked cells on commercial-grade textured CZ silicon wafers, as certified by ESTI. One of the key challenges with such a tandem structure is stacking the perovskite on top of crystalline silicon cell, as the latter has a textured surface. LONGi has a technology breakthrough in the process of creating this interface (see LONGi Tandem Cell Record).

The text is an excerpt from TaiyangNews New Solar Products Overview H1/2023, which can be downloaded for free here.