TOPCon has been knocking on the doors for quite some time now, presenting itself as something to look forward to beyond PERC. From the perspective of former n-PERT players, TOPCon was the light at the end of a tunnel darkened by the heft and vast knowledge pool of PERC. Back when it arrived on the scene, it did attract a few of the large players, who somehow seemed to lose interest, or at least didn't make desired progress, as time passed. And despite being touted as a natural upgrade from PERC, TOPCon represents only a small fraction of the market so far.

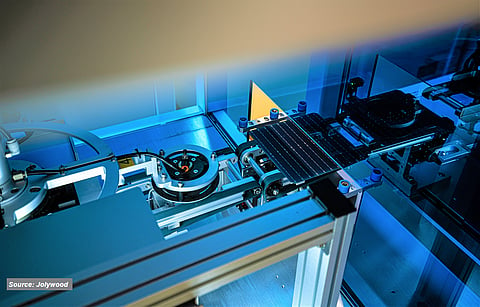

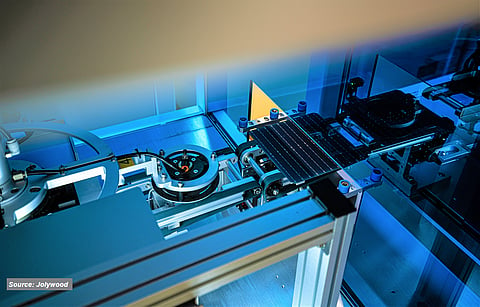

Jolywood has been the only manufacturer of note for TOPCon a while, as most companies are either testing/piloting or running small production lines. There are teething issues with any new technology, and scaling up from R&D to production does take time. It wasn't too long ago that PERC faced the same hurdles. And TOPCon is to PERC what PERC was to BSF. It brings the same performance advantages and probably the same number of additional process steps.

Its resemblance to PERC in terms of structure as well as manufacturing are undeniable advantages — one up over its key contender HJT. And the similarity extends to even scaling up to larger wafers.

The technology isn't hugely popular, as evidenced by the little following it has garnered. And LPCVD, given its inherent limitation of wraparound, is largely to blame, apart from the higher number of process steps and associated costs, and low process yields. Not only are there alternative technologies becoming available, there are even tweaked tool designs for LPCVD that can alleviate the wraparound issue. And new deposition technologies are coming into play with the promise of reducing the total number of process steps. As competition among the deposition technologies, as well as the tool vendors, increases over time, it is safe to assume that there is going to be a gradual reduction in CapEx with time. And as innovative tool platforms are introduced and the process sequence optimized, one can see the 15-20% cost gap between TOPCon and PERC being narrowed (see LPCVD For TOPCon Cells).

Things are looking up for TOPCon over the past few months, as we saw at the world's largest solar trade show SNEC in 2021. The power and efficiency delta to PERC, which wasn't so high with earlier generation products, has started to widen with the latest product ranges. Pilot lines have also started growing bigger, not just because of the growing interest, but also larger wafers and high throughput machine platforms.

The breadth of TOPCon modules showcased at SNEC 2021 was a surprise on the positive side. In terms of what it means for commercial production, it is too early to say. It is going to be a wait-and-see whether TOPCon fizzles out or has what it takes to become a worthy successor for, and as successful as, PERC. However, one of the world's largest module manufacturers, JinkoSolar has now opted for TOPCon – and is heavily investing. When we talked in January to JinkoSolar's Global VP Dany Qian on their plans for TOPCon, she said the company's production capacity will reach 16 GW by year end (see A Big Mid-Term Plan For TOPCon). Jolywood is already targeting expansion of its capacities to over 20 GW. It looks like the door for TOPCon is starting to open.

This is the updated conclusion part from TaiyangNews report on TOPCon Solar Technology, which is available for free download here.

Our TaiyangNews Conference on High Efficiency Solar Technologies, on Day 3, focussed on TOPCon Cells. To learn more about the conference and view the presentations from various technology leaders click here

.png?w=50&fm=png)