First day of TaiyangNews Global PV System Technology Trends H1/2024 event had world’s leading module makers present latest product innovations launched at SNEC and Intersolar Europe this year

Manufacturers are designing and planning products to suit various application needs

More and more modules are going busbarless for costs and performance benefit

Modules supporting anti dust accumulation is also a common topic among the module maker

Two of the world’s largest solar PV shows this year — SNEC in Shanghai, China, and The Smarter E /Intersolar Europe in Munich, Germany — were not only packed with an a record number of exhibitors and attendees, but also showcased an incredible amount of technology innovations.

TaiyangNews brought together leading names in the global solar PV industry to present their latest products launched at these events, at the 2-day Virtual Conference on Global PV System Technology Trends H1/2024, of which the first day took place today, on July 30, 2024.

In his keynote address TaiyangNews Head of Technology Shravan Chunduri shared the TaiyangNews Top Modules High-Efficiency Update for H1 2024. Being published for over 2.5 years, the list now is 30 editions old. Chunduri described the idea behind launching a half year report on these as providing enough fodder to analyze various trends over a long term – and the latest one analysing H1 2024 for published during SNEC and Intersolar (see TOP SOLAR MODULES H1/2024).

The number of products included in the 1st list in January 2022 totaled 20, but by June 2024, the same went up to 57. However, the number of companies on the list did not grow as much. These started from 19 and have stayed at 33 for the last few months. According to Chunduri, this points at the fact that more and more manufacturers are working on more than 1 module technology.

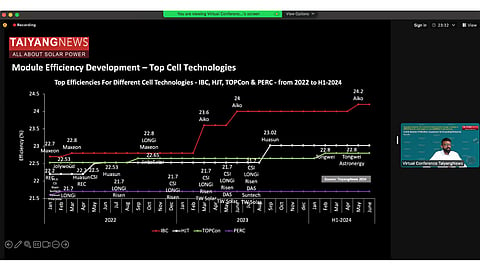

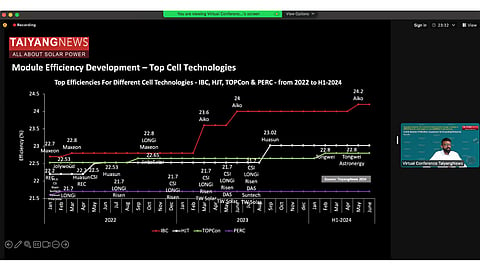

As for module efficiency, the highest increased by 0.1% in 2022 from 22.7% to 22.8%, but it jumped twice to 23.6% and then to 24% within 2023, and then again to 24.2% in H1 2024. The highest efficiency is represented by back contact (BC) technology, led by China’s AIKO, and followed by Singapore’s Maxeon, which is majority-owned by China’s TCL.

Being the industry workhorse for several years, PERC modules still dominate the list, but it is ‘not a subject of improvement anymore’, stressed Chunduri. Its development is stagnating since its highest efficiency remains at 21.7% for several months. None of the PERC products listed in the TOP MODULES list have undergone any change in the entire H1 2024.

Additionally, high power modules of over 600 W range feature prominently on the list with 45% share, whereas the share for the mid-power range (500 W to 600 W) is growing. However, the commercially available highest power modules are 715 W HJT prodcuts of Huasun and TW Solar, which is somewhat less than the 750 W or so modules sometimes displayed at SNEC and Intersolar.

JA Solar’s Senior Engineer Weichen Jin presented the key features of the company’s TOPCon technology and its customer-centric solutions approach during her presentation.

While sharing the JA solar cell R&D roadmap, Jin shared that it had been working in-house on developing TOPCon technology since 2017. Its large format TOPCon solar cell with 330 cm² area has listed into the latest《Solar cell efficiency tables》(64 version).

The manufacturer is now working on other technologies such as HJT, XBC, and even tandem. These should be ready for commercial use once there is enough demand in the market, she added.

JA pointed out that they have designed “reliable product solutions for different applications”. These include products with optimized BOM solutions for ocean, plateau, desert or humid areas.

Jin also shared the company’s module solutions for various applications, especially rooftop solar which she said will be a growing segment over the next few years.

Moreover, to ensure its single-glass TOPCon modules are well suited for the rooftop segment, it has worked on cell and encapsulation optimization. It also developed patented anti-dust design for the frame with drain holes on the short frame, a topic that could be also seen by other manufacturers presenting at the conference, like Trina or LONGi.

One of the world’s largest solar PV manufacturers, LONGi called its back-contact solution as the ‘ultimate’ technology. LONGi’s Product Marketing Manager Dante Zeng relayed the journey of the company’s Hybrid Passivation Back Contact (HPBC) 2.0 development. The 2.0 version has superior conversion efficiency, power, temperature coefficient and higher reliability compared to its previous generation, he explained.

LONGi said it achieved 25.5% mass production cell efficiency using its 1st generation HPBC technology. With the 2nd generation introduced in 2024, based on the company's self-developed n-type TaiRay wafer, it is pursuing the ultimate efficiency of 26.6% that also has the potential to reach 27%. It recently has introduced a 24.4% efficient module series, called Hi-MO9 with up to 660 W power output.

In general, with HPBC LONGi modules have no frontal gridlines, have full field hybrid passivation on the front and back side, anti-reflective coating and passivation layer that, as Zeng explained, make it a powerful and aesthetic product to match diversified scenarios.

Offering a comparison between TOPCon and the company’s self-develop HPBC technology, he claimed the latter performs 1.54% higher than TOPCon under low-light conditions. With its unique electrode paste that uses only 1/6th of lead compared to TOPCon, LONGi’s product claims to have better resistance to degradation in humidity and heat environments.

What’s interesting – only recently companies compared the advantages of their new technology – HJT or TOPCOn - to PERC. Now that TOPCon is the new standard, those opting for other technologies try to point out the benefits of not going TOPCon.

However, there’s still quite some optimization potential for TOPCon. One of the market leaders betting these days on TOPCon is Trina. Talking about the company’s i-TOPCon n-type technology, Trina Solar’s Product Manager Ling Zhuang introduced its latest module solution NE19R.70 anti-dust panels that will be available in the market in the near future.

These anti-dust Vertex N modules have up to 630 W output and an efficiency level reaching 23.3% based on G12R wafer size. Explaining the focus on anti-dust modules, Zhuang said dust is a major culprit for causing shading while also posing the risk of damage to the coating. It can lead to chances of hot spot and reduce power generation of modules.

Its patented anti-dust frame design reduces the contact angle of water by shortening the exposure of frame, will ensure that dust is easily washed by rain or wind.

She also shared the company’s overall production capacity targets for 2024 as 120 GW for modules, 105 GW for cells, and 60 GW for silicon wafers.

Another company that is fully focusing on TOPCOn these days is JinkoSolar, the first of the major players expanding in this field. Solutions Engineer at JinkoSolar, Andy You presented the company’s PV technology and global manufacturing strategy 2.0. Under this, the manufacturer plans to explore integrated, collaborative and sustainable approach to expanding production capacity.

You referred to the company’s recent agreement for 10 GW solar cells and 10 GW module production in Saudi Arabia (see Solar Manufacturing Consortium In Saudi Arabia). As it targets further expansion in the near future, JinkoSolar’s 2.0 era will see it continuously evolving its manufacturing and marketing strategies to expand global presence.

He also touched upon the company’s sustainability efforts with n-type TOPCon Tiger Neo Solar Panels, produced in its TÜV Rheinland certified Zero Carbon Factory. JinkoSolar claims to be the 1st in the industry to have this certification for every step of its manufacturing process, namely silicon ingot, silicon wafer cutting, solar cell, and solar module manufacturing. Sustainability is becoming a hot topic among solar manufacturers – and more and more companies are trying to score in this rather new field to the solar sector, which for a long time felt it’s inherently green.

He also shared some of the test results to prove the good performance of Jinko's TOPCon modules. Subjecting its modules to UV180 + DH1000 test under which the company significantly increased the testing conditions with higher irradiation at 180W/m2 for 1,000 hours and applying damp heat (DH) conditions simultaneously, it recorded only 2.93% power degradation for Tiger Neo modules. The passing standard is 5%.

Similarly, an empirical analysis of the modules revealed that the total energy production of TOPCon modules was 1.13% more than that of BC modules.

Tongwei Solar’s Aran from its overseas technical support, showcased the company’s TNC-G12R modules while calling this format the ‘best new gene’. Its flagship modules, with TNC-G12R format of 182mm x 210 mm wafer size, TNC-G12R 48 caters rooftop and distributed projects, while the TNC-G12R 66 is for the C&I and utility segment, TNC-G12R 54 is for distributed projects especially for carport.

Higher module output, improved efficiency reduced transportation cost, leading to lower balance of system (BOS) and lower levelized cost of electricity (LCOE) were some of the benefits of the TNC-G12R format that Aran listed during her presentation at a time the number of cell formats has increased after the era of half cells started only recently. Aran also shared the “Size Map” of the company with respect to cell technology:

TOPCon – 210 x 210 mm, 182 x 210 mm & 182 x 183.75 mm

HJT - 210 x 210 mm

In terms of the company’s production capacity roadmap, Tongwei’s existing polysilicon production capacity is 650,000 tons/year, and that for solar cell it is 95 GW. By 2026, it targets to increase the same to between 800,000 to 1000,000 tons/year, and within 130 to 150 GW, respectively. Tongwei’s current solar module production capacity stands at 75 GW, and monocrystalline wafer at 20 GW.

Astronergy Product Manager Zeyu Li shared the salient features of its ASTRO N7 and ASTRO N7s technology products, both based on TOPCon technology.

Calling TOPCon the main product in the market today, Li said one shortcoming for TOPCon cells is that these require a higher temperature process, and more fabrication steps compared to HJT, however, it has high compatibility in the industrial chain.

Following the trend of rectangular wafers, Astronergy too uses 210 or 182 wafer sizes for its ASTRO series. According to Li, the rectangular wafer size offer financial advantage in terms of optimizing shipping container space and reducing shipment costs while lending more power and reliability. Its use it set to grow in the industry.

Astronergy targets to scale up its module production capacity to 75 GW by the end of 2024, with TOPCon making up 85% share. By 2025, TOPCon will have 90% share in the company’s overall 100 GW module capacity target, as per its roadmap.

AIKO’s Product Solution Manager Jiayu Ma introduced the company’s Infinite all back contact (ABC) solar module that it launched at SNEC this year touting 25% efficiency, which it plans to launch at the end of this year (see AIKO’s New Products for Residential & C&I). With 0BB, the current goes directly from finger to solder joints, thus reducing the electrical loss, unlike multi busbar (MBB).

Infinite uses ultra-high resistance silicon wafer to break through the efficiency bottleneck, she explained. It has better temperature coefficient with a bipolar passivated contact, ensuring lower degradation of 1% in the 1st year, and 0.35% annually.

One major feature of the Infinite module is that it uses precise overlap welding to eliminate cell spacing, leading to 0.5% increase in active area. Compared to conductive adhesives in traditional shingled, and Z shape traditional overlap welding, ABC overlap welding is more stable and can avoid micro cracks, stressed Ma.

Very interesting point is the Infinite product hiding Bus ribbon to achieve real full screen, which can increase 1.1% of effective power generation area and 8W power increase on standard dimension 2,382 mm x 1,134 mm module.

The day 2 of the conference on July 31, 2024, will see several more leading names from the global solar PV industry sharing their latest innovations as unveiled during SNEC and Intersolar 2024, with a keynote from Exawatt. Registrations are free here.