Emitter formation remains one of the most established processes in cell manufacturing, traditionally realized in batch-type tube diffusion furnaces

The industry shift from atmospheric to low-pressure diffusion has enabled higher sheet resistance emitters

For TOPCon on n-type wafers, boron diffusion using BCl₃ has become mainstream, offering cleaner tubes and better gettering

Solar cell manufacturing is a chain of interconnected processes, where nearly every step is linked to at least one other. For instance, surface preparation is closely tied to passivation, while metallization impacts both interconnection and emitter formation. Another factor that influences emitter formation is metallization. Emitter formation comes after the very first step of surface preparation – SDE and texturing– and is perhaps the most robust and mature process in cell processing.

From a physics point of view, a solar cell is essentially a p-n junction diode, and the wafers entering the cell lines are base-doped (p- or n-type). To realize a solar cell from these incoming wafers, the emitter is formed by doping the silicon substrate with a polarity opposite to that of the base. Diffusion is the most prevalent technology used for forming the emitter in solar cells, typically in diffusion furnaces. Fundamentally, there are 2 variants of diffusion furnaces: conveyor-based inline tools and batch-type tube furnaces. While the former is now completely extinct, tube-type furnaces are the unanimous choice for the application.

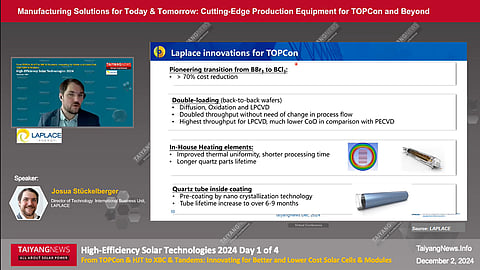

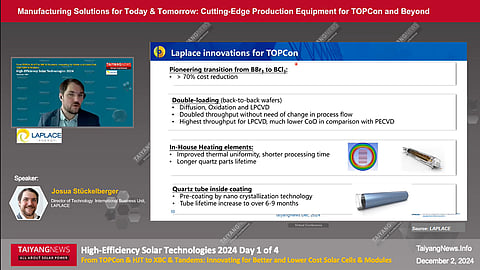

Another technology shift that has occurred in this segment is the industry’s move to low-pressure diffusion. The traditional diffusion furnaces were typically operated at atmospheric pressure. The shift to low-pressure diffusion facilitates the formation of a high sheet resistance emitter, reaping the full benefits of the developments in metallization pastes, which assumed the role of the state of the art several years ago. Semco from France was the first to develop low-pressure diffusion furnaces, and eventually, as the technology gained uptake, every equipment supplier began offering such low-pressure diffusion furnaces. Of late, it is China’s LAPLACE that has spearheaded the technology (see LAPLACE Advances TOPCon With Poly-Finger Designs & Cost-Reduction Strategies).

Since TOPCon technology is mainly adopted on the n-type wafers, the emitter is formed through boron diffusion. It is not just a change of the precursor. Boron diffusion is often accomplished at a higher temperature – above 1,000°C – and requires higher cycle times, resulting in lower throughput. One interesting development with respect to the boron diffusion process is the choice of precursor. Boron tribromide (BBr3) was the most extensively used precursor in the past, but it has one inherent side effect: the byproduct of the process acts as a glue to quartz, which may reduce uptime.

While equipment makers have significantly optimized the process, Semco switched to boron trichloride (BCl3) a long time ago, based on the belief that it delivers better results, as the presence of chlorine keeps the tube cleaner. It also helps in gettering. BCl3 is supplied in a gaseous form in bottles, eradicating the need for bubblers. BSG, with a chlorine-based precursor, is easy to remove compared to its counterpart. The flip side of using BCl3 is its corrosive nature and the associated safety concerns. Nevertheless, it has now become mainstream. LAPLACE has played a pioneering role in advancing diffusion furnaces, especially for TOPCon technology. The company introduced the BCl3-based process to China. The most significant developments in the emitter formation segment are related to TOPCon, and indeed, several changes occurred in this segment within a short span of time.

The text is an edited excerpt from TaiyangNews’ latest Market Survey on Solar Cell Production Equipment 2025, which can be downloaded for free here.