Anti-glare and dual-layer ARC coatings on solar glass enhance light absorption and reduce reflectivity

New module frame designs with self-cleaning features and drainage channels help reduce dust accumulation

Alternative frame materials, such as steel and composites, are being adopted due to their higher mechanical strength and lower carbon footprint

Developments in Solar Glass

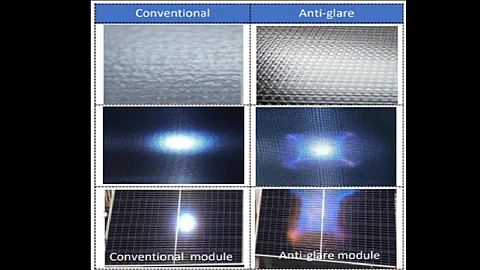

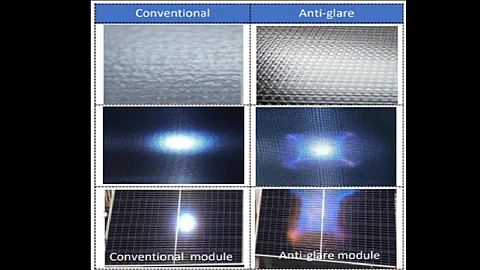

Innovations in glass are playing an increasingly important role in enhancing solar module performance and expanding their range of applications. To maximize light absorption, solar glass is now commonly treated with 2-layer antireflective(ARC) coatings to reduce reflection to the maximum extent possible. On the other hand, polymer-based frontsheets are also replacing glass, though the spread is rather niche. In addition to boosting transmittance, some module manufacturers are adopting anti-glare glass solutions. Unlike standard glass, which can cause significant reflection, anti-glare glass is engineered to diffuse light and minimize glare. This development has eased the restriction of solar deployment in sensitive areas such as airports and highways, where controlling reflectivity is critical for safety reasons. The effectiveness of anti-glare technology is notable: the reflectivity of modules using anti-glare glass is typically only 20% to 30% of that observed in standard modules. As a result, anti-glare glass not only supports better integration into specialized environments but also helps broaden the overall application scope for solar energy systems (see BOM Innovations For Advanced Solar Modules).

Innovations in Frames

Dust accumulation has long been a challenge for traditionally framed solar modules, particularly along the lower edges, where settled dirt can block sunlight and lead to significant power losses over time. To address this, several manufacturers have introduced innovative frame designs aimed at minimizing dust buildup. A common feature in these new designs is the inclusion of drain holes on the short sides of the frame, allowing water and dust to be washed away more easily. However, design improvements are not limited to drain holes alone. More sophisticated frame profiles are being developed to promote better self-cleaning behavior and reduce maintenance needs, ultimately helping to sustain module performance over the long term. Another area of innovation is the exploration of alternative frame materials. While aluminum remains the dominant choice due to its light weight and corrosion-resistant properties, steel frames are beginning to gain traction. Steel offers better mechanical strength and comparable durability, while also providing advantages in sustainability with a lower carbon footprint and offering cost benefits. The trade-off is a slight increase in module weight, but several manufacturers are actively evaluating steel frame options, with some already introducing products to the market. Additionally, composite frames are also being explored as a lightweight and potentially more sustainable alternative, further diversifying the options available for advanced solar module designs.

This text is an excerpt from the TaiyangNews Cell & Module Technology Trends 2025 report, which can be downloaded for free here.