Dow has rolled out its latest silicone gel tailored for 7th generation IGBT devices, which can endure an operating temperature of up to 180°C

The 2-part gel, featuring Part-A and Part-B, can be cured either at room temperature or with forced heating

The product is commercially available globally

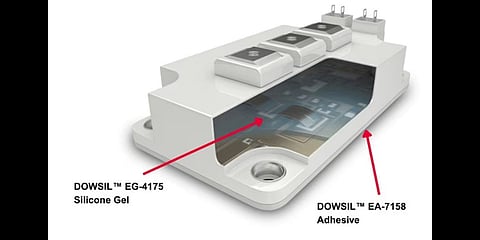

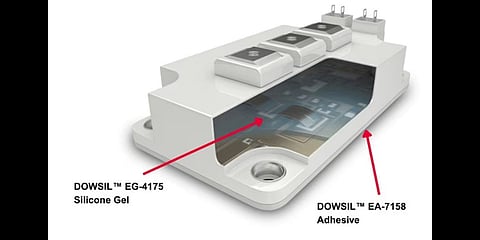

Dow, the leading US-based material science company, recently launched its latest silicone gel, DOWSIL EG-4175, tailored for the 7th generation of insulated gate bipolar transistor (IGBT) based power electronics devices.

Chief among the product’s key features is its maximum operating temperature of 180°C, which is higher than that of its earlier versions. It is a 2-part gel – Part-A and Part-B – mixed in a 1:1 proportion, and can be cured at room temperature, or what the company characterizes as a ‘no flow state’. Curing can be accelerated through external heating, reducing the cycle time for mass production. This gel can also be cured into an extremely soft material, which offers protection to the delicate IGBT device. At the same time, it offers dimensional stability, similar to an elastomer. It also provides relief against thermal and mechanical stresses stemming from continuous switching of the isolated circuits. The company claims that the cured composite exhibits self-healing properties, repairing small cracks on its own.

In addition to mechanical properties, this cured gel isolates the embedded circuits of the stack and provides electrical insulation against the rated operating voltages. It has a dielectric strength of up to 23 kV/mm, required to endure a maximum operating junction temperature of up to 180°C without failure. Featuring a volume resistivity of up to 5.4E+15 Ω cm, the cured gel protects the isolated circuits from external environmental stressors such as moisture and contaminants.

The company states that this gel can also be used in combination with its existing silicone adhesive, DOWSIL EA-7158 – a 1-part non-flowing silicone product that cures with heat and offers adhesion to diverse substrates without using primers.

According to the company, both products – silicone gel and silicone adhesive – are commercially available globally.