Germany-based technology startup LuxChemtech GmbH has signed a cooperation agreement with Meyer Burger Technology AG to carry out solar cell and module recycling. For this, a new plant is being commissioned at LuxChemtech at Freiberg in Germany where Meyer Burger has been operating its module fab since 2021.

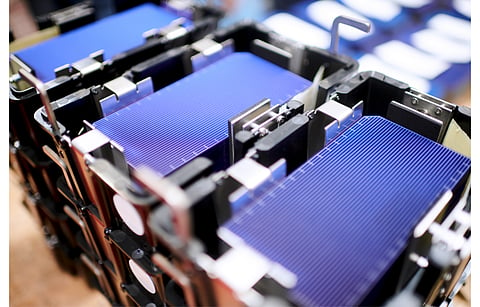

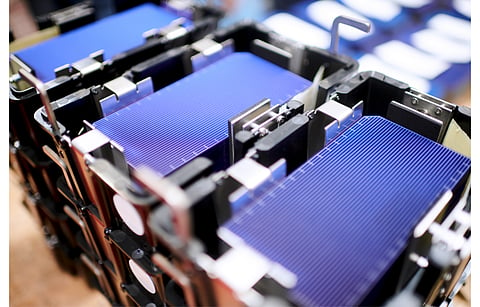

Under the agreement, Meyer Burger will provide glass, foils, aluminum and cell fractures among other residues from PV production to LuxChemtech that will then process the same to recover valuable materials as silicon and silver. These will be returned to the economic cycle.

The Freiberg plant is also suitable for complete dismantling of solar modules and cells.

"If I want to produce high-tech, I also need the right ingredients," said CEO and Co-Founder of LuxChemtech. "In Germany, we have hardly any raw materials worth mentioning for this and therefore have to import. This is where our Recycling 4.0 is needed – with sophisticated technology we want to save the precious raw materials from solar products, such as silicon and silver and ideally recycle them."

In a press statement, Meyer Burger said a demonstration plant for processing solar modules in Tangermünde, Saxony-Anhalt, is scheduled for commissioning in 2024.

For LuxChemtech, this is its 2nd cooperation agreement with a European module manufacturer in recent times, following one signed with Lithuania's SoliTek recently. The latter said with LuxChemtech, it will be involved in managing its PV module waste and ensure its recycling using latest technologies.

Additionally, SoliTek will also share its full material content data with LuxChemtech on the changes it makes in PV module design or materials to have the latter test its modules on recyclability. The Lithuanian manufacturer said LuxChemtech will be privy to its sales volume for it to be able to forecast expected PV waste more accurately.

SoliTek is also giving an option to its clients to have their PV waste processed using LuxChemtech's recycling technologies.

Recycling and reusing solar panels as part of the solar industry's sustainability measures were discussed at length at the TaiyangNews 1stSolar & Sustainability Conference 2023. Presentations by participants during the event are available for viewing here.