Backsheets, due to their multilayer construction, offer enormous potential for technical as well as economical optimization. Either of these dominates according to market demand. For the year 2022, one of the major trends in the backsheet segment was the high price of PVDF, the raw material used to build the most famous backsheet structure (KPC). As a result, the market has shifted to the CPC structure within no time. While CPC capitalized most from PVDF's fall, so did non-fluoropolymers, at least partly. The increase in PVDF prices has pushed non fluoropolymer backsheets also into limelight, thereby on the radar of a few module makers even in China, where the belief in the past was that a fluoropolymer film is a must to realize the required UV protection. This appears to be changing (see High Price Of PVDF Is The Hot Topic).

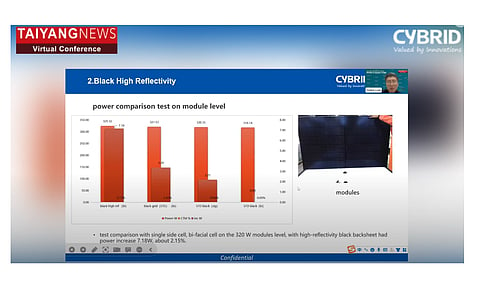

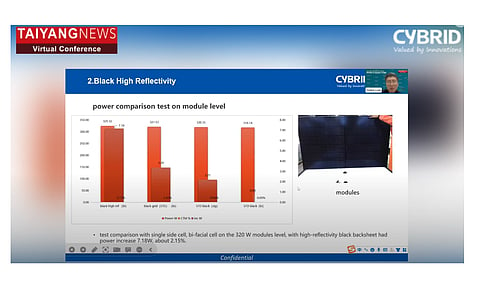

Due to an increase in the deployment of bifacial technology in utility solar, a segment that primarily prefers the glass-glass structure, backsheets found the residential segment becoming more and more important. Black backsheets are gaining popularity, and backsheet makers are enhancing their offering with the reflective black backsheet. At the same time, there is a hard push on the part of backsheet suppliers to replace glass with the transparent backsheet in bifacial applications. In fact, the US seems to be one market where the idea has been well received. Transparent backsheets with grid, especially black grid, are gaining recognition. Innovations associated with transparent backsheet, reflective black backsheets, non-fluoropolymers are also the key points covered by Cybrid's senior product manager Stephen Gong, at the TaiyangNews Reliability 2022 conference (see Cybrid's presentation recording here).

Sustainability, low carbon footprint, recyclability are factors that have also started to find appeal among Chinese backsheet makers. A sure indication of that can be seen in companies like Crown promoting non-fluoropolymer and Cybrid building huge capacities for the same. The choice here is mainly PET; however, coextruded PP backsheets are also gaining traction on this account. Speaking at the TaiyangNews Virtual Conference on Solar & Sustainability 2023, Imco Goudswaard, Commercial Manager & Sustainability Lead at Endurans was of the view that backsheet material choices made today will have a big impact in 30 years. Traditional backsheets are likely to end up in landfills with a 500 kton/year volume by 2050 without being recycled, but Endurans Solar says its HP circular backsheets can be recycled using high efficiency pyrolysis and reused (see Endurans' presentation recording here)

Backsheets with low WVTR, especially for advanced cell architectures such as TOPCon and HJT, are also an important trend in the segment. While not a hot topic, backsheets compatible with larger module formats still continue to attract some attention in a few cases (see Backsheets Manufacturers Update).

The article is an updated excerpt from the TaiyangNews Market Survey on Backsheets and Encapsulation 2022-23, which can be accessed for free here.