Key takeaways:

BT Imaging offers PL and defect analysis tools from wafer to module stages, for both offline and inline use

The R3 series can characterize multi-junction cells, such as tandem and perovskite cells, including large-area formats

New i5 and M5 series are designed for seamless integration into high-speed production lines, offering real-time quality insights

Characterization tools are critical to quality assurance in PV manufacturing, right from the ingot stage to the final module. Improvements in cell and module efficiency often stem from better wafer quality and surface passivation, which are validated using various characterization methods. Among these, photoluminescence (PL) plays a key role by helping manufacturers observe and enhance the quality of wafers and cells.

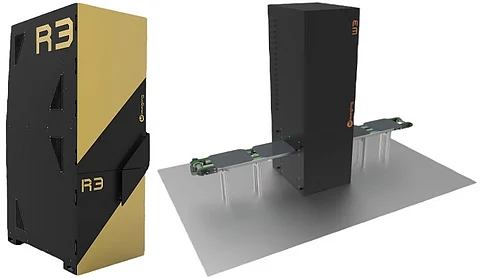

BT Imaging is one such company offering a broad range of PL imaging tools to support PV manufacturers. The company’s current lineup includes offline tools under the R3 series, designed for both R&D and production use, while upcoming inline tools are aimed at integration across the entire PV production line, from ingot to wafer, to wafer to cell, to cell to module. BT Imaging’s future lineup of products enables the implementation of characterization imaging tools at almost every step of the process.

The R3 series supports PL imaging for wafers, in-process wafers, and finished cells. In addition, the system provides complementary characterizations such as electroluminescence (EL), Rs (shunt resistance), and efficiency mapping. For cells, it can generate contactless I-V and Suns-Voc curves along with related performance metrics. These features allow manufacturers to pinpoint and quantify defects early, enabling corrective actions to improve wafer and cell quality.

Variants of the R3 system can also analyze multijunction devices, including tandem cells, slugs, and even single-junction perovskite cells. The second-generation PL imaging in these tools is said to offer enhanced resolution, aiding better defect analysis. The R3 multi-junction variant supports small and large-area tandem cells (up to 210 x 105 mm²), simulates real sunlight exposure, and generates I-V curves. It also features imaging capabilities specific to top and bottom sub-cells and offers additional services through subscription. Notably, this tool includes a patent-pending, IR camera-free Rs imaging technique.

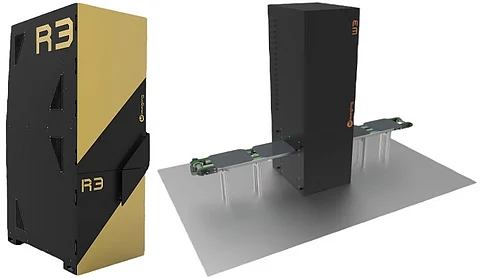

For mass production, BT Imaging is developing advanced inline tools that allow for early defect detection and quick diagnostics, even for partial cells. These inline solutions aim to eliminate the traditional need for end-of-line defect detection. They are designed to integrate easily into xBC and 0BB/SMBB production lines without major hardware changes.

The inline lineup consists of 2 series: i5 series – tailored for wafers and cells; M5 series – focused on cell strings and modules, both pre- and post-lamination.

The i5 wafer tool is capable of inspecting over 10,000 wafers per hour. It offers measurements such as wafer thickness, resistivity, ring and circular defect severity, and estimated short-circuit current (Jsc) and open-circuit voltage (Voc) limits for the finished cell. The i5 pre and i5 cell variants, which operate at different cell processing stages, can detect 11 defect types and provide root cause analysis.

Together, these inline and offline tools aim to cover the full spectrum of PV manufacturing diagnostics and are designed to work in tandem with BT Imaging’s module-level characterization systems.