Jinko ESS’s latest SunGiga G2 ESS is equipped with 135 kW PCS

Compared to its predecessor, the ESS features a non-uniform flow-based liquid-cooling mechanism that helps limit the cell-to-cell temperature delta to 2 °C

Its storage capacity can also be scaled up to 3 MWh by connecting 12 units in parallel

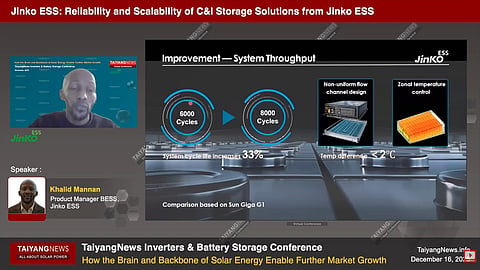

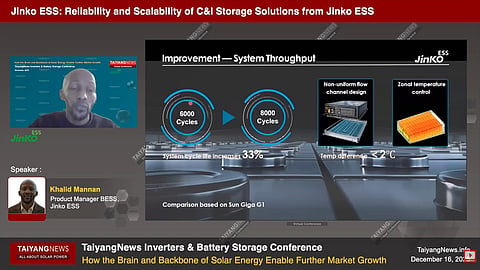

With a focus on Europe’s commercial & industrial (C&I) energy storage market, Jinko ESS, the storage arm of Jinko Solar, introduced its 2nd-generation integrated storage solution, SunGiga G2 ESS, with a 261 kWh capacity. Speaking at the TaiyangNews Inverters and Battery Storage Conference, Khalid Mannan, Product Manager, BESS, Jinko ESS, provided details about the product.

The SunGiga G2 energy storage system (ESS) features 5 vertically stacked battery packs, a power conversion system (PCS), and an air-cooled chiller in a metal enclosure. Each battery pack is equipped with 52 lithium-iron-phosphate (LFP) battery cells (314 Ah and 3.2 V), connected in series and delivering a DC voltage of 832 V. The system's cumulative energy storage and discharge capacity (5 × battery pack) is 261 kWh. When the battery rack is interfaced to a 135 kW (3-phase AC) bidirectional PCS, the ESS delivers backup for up to 2 hours at the nominal discharge rate. Mannan says, unlike its predecessor, SunGiga G1, this ‘all-in-one' design allows vertical assembly, which helps reduce system volume by up to 10% and increase energy density. In addition, each battery pack’s operating temperature is controlled by a non-uniform flow of a circulating liquid coolant through metal channels on the rear side. It aligns with the non-uniform temperature distribution across the battery cells and helps maintain a cell-to-cell temperature delta within 2 °C. This attribute increases the system lifecycle to up to 8,000 cycles (charging/discharging) and up to 70% end-of-life (EOL) capacity. Regarding scalability, the total system capacity can be increased to 3 MWh by connecting 12 units in parallel. Its pre-factory assembled design allows rapid on-site system installations.

Given the critical nature of an ESS’s safety aspects, the company adopts a protection feature that covers 5 layers: battery cells, unit, pack, rack, and system. While abnormalities (voltage & current) of each cell are monitored in real-time, the cell-to-cell gap is protected against potential thermal runaway by mica flakes. In addition, each battery pack is housed in a composite material enclosure with a top insulating layer and an explosion-proof valve to prevent gas formation during untoward events, such as an electric arc. It’s built-in fuse also protects against short-circuits. At the system level, the gas and temperature sensors automatically detect any anomaly and activate the alarm.

On the application side, this ESS supports demand response from C&I customers and provides backup power to commercial buildings with large connected loads in off-grid mode. It can also offer power arbitrage by storing energy during low-tariff periods and discharging at peak load hours of the day, typically at high tariff rates. Furthermore, this system can act as an independent microgrid.