In the current era of terawatt (TW)-scale PV installations, a vertically integrated PV module manufacturer’s transition to new products in the short term depends on several key factors: global trends in cell technology and shipments, shifts in wafer sizes, and market demand for scenario-based modules. Navigating a product outlook that aligns with global market trends is essential for ensuring a sustainable future, both in the short and long terms.

At the recent TaiyangNews High-Efficiency Solar Technologies 2024 Virtual Conference, Leo Cong, Product Manager at JinkoSolar, provided an insight into the company’s 2025 product outlook (see Jinko Solar presentation here). This outlook is shaped by both silicon cell technology trends and the evolution of the market.

Evolution in Jinko’s Cell Technology

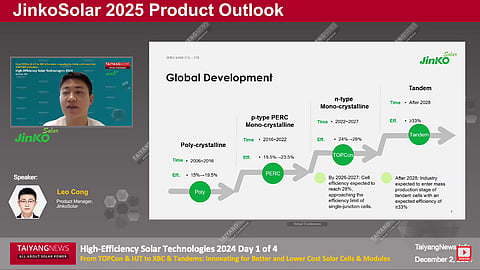

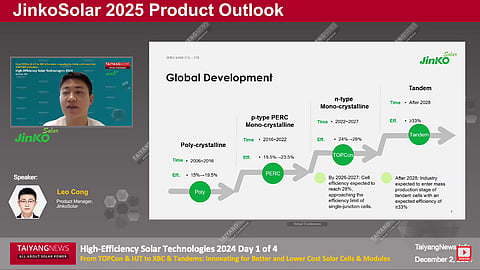

Cong began his presentation by discussing the global evolution of cell technology, from 2006 to post-2022 – from p-type PERC to monocrystalline, followed by the transition to n-type cell technology. JinkoSolar, as the first company to launch a mass-produced 182 mm size TOPCon cell-based product series, is continuing to focus its R&D efforts on TOPCon technology. This aligns with the company’s vision that, within the next 3 to 5 years, or by 2027, TOPCon will remain its mainstream product. By the end of 2027, when the efficiency of single-junction cells is expected to reach the limit of around 28%, JinkoSolar anticipates that the industry will transition to mass production of tandem cells, with expected efficiencies of up to 33%.

Reflecting market trends, JinkoSolar began with 800 MW of p-PERC technology products in 2021, transitioning to TOPCon technology mass production with its 182 mm wafer-size Tiger Neo product series by the end of 2022. Since then, the company has placed an increased focus on improving cell efficiency.

Cong noted that the company's mass-produced TOPCon cell—dubbed HOT 2.0 technology—achieved up to 25.8% efficiency in 2022. This evolved into the HOT 3.0 cell, featuring ME technology and an efficiency range of 26.5% to 27%, beginning in 2024. The HOT 3.0 technology will feature in JinkoSolar’s Tiger Neo 3.0 product series, which is slated for release in 2025.

Looking further ahead, JinkoSolar aims to reach up to 28% efficiency with HOT 4.0 cell technology, which will feature advanced elements such as 0BB and HCP between 2025 and 2028. A new, confidential cell structure is expected to be incorporated into the company's products by 2025.

Cong shared some data from InfoLink Consulting, which indicates that n-type cell technology, specifically TOPCon, is expected to capture up to 68% of the market share in 2024, and this share is predicted to remain around 70% in the coming years. The company also observed that, as of early 2024, manufacturers were still evaluating which rectangular wafer size to adopt. However, increasing numbers of companies are choosing the 182 x 210 mm, or M12R, wafer sizes. Data from H1 2024 showed that 210 mm wafer-based products accounted for 26% of the market share, while 210R wafer-based products accounted for up to 8%.

Currently, JinkoSolar's mainstream products include the N66HL5-BDV utility series, featuring 210 x 210 mm wafers, while traditional 182 mm wafer-based modules include the N78HL4-BDV and N72HL4-BDV. However, beginning in 2025, the company will shift more toward bifacial dual-glass products. Additionally, distributed market products, which currently feature 54 pieces of 188 x 182 mm wafers, will transition to 210 x 182 mm or 210R wafers. Furthermore, JinkoSolar plans to offer scenario-based products, including modules with higher hail resistance, high wind load resistance, and improved fire classifications, designed for regions with high environmental requirements, such as the US market.

The Tiger Neo 3.0 module, featuring HOT 3.0-type 210R-size cells, will have a power output of up to 670 W and an efficiency of up to 24.8%. This product is set to be released in 2025, with small-scale orders beginning in Q4 2025 and large-scale orders expected to start in Q1 2026.