Chinese solar module and backsheet producer Jolywood says a new PV cell injection metallization technology developed by the company can pave the path for designing TOPCon modules based on glass-backsheet configuration, while double-glass is the state-of-the-art. That's mainly because the former configuration often shows larger degradation than the spec in reliability tests protocols such as the damp heat test.

While it sounds counterintuitive, there is a strong correlation between metallization and reliability. Typically, aluminum-doped silver paste is applied to TOPCon cells with p-type emitter to take the shape of the metallic contacts on the front side. Any moisture ingression, which is comparatively more with the glass-backsheet configuration over double-glass, along with heat, accelerates the oxidation of the aluminum, thus leads contact thereby power degradation.

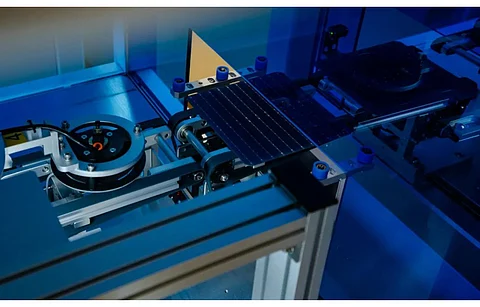

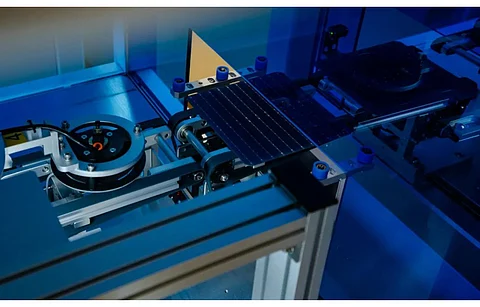

To overcome this issue. Jolywood has developed a technology called JSIM, or Jolywood's unique injection metallization technology, it uses a new paste chemistry on the front surface of TOPCon to form a reliable contact interface between the metal conductor and the silicon substrate, thereby reducing the risk of contact damage. The solution not only solves the sensitivity of front metallization to moisture ingression, heat and encapsulation materials, if any, but also reduces contact resistance and recombination current density, boosting cell efficiency. "This lays a technical foundation for single-glass encapsulation of bifacial TOPCon cells.

Long-term laboratory verification testing conducted in-house by Jolywood show that the modules with JSIM successfully passed the 2,000-hour damp heat test sequence at 85°C and 85% humidity conditions.

It claims, "This is enough to prove that Jolywood's JSIM technology has perfectly overcome the realibility problem of single-glass bifcial TOPCon modules under long-term humid and hot conditions."

JSIM can be easily combined with Jolwyood's transparent backsheet irrespective of the encapsulation material opted, including EPE, POE and EVA.

While Jolywood has not provided the name of the paste vendor, Solamet announced the development of "First Commercial TOPCon Laser Carrier Paste" also for TOPCon cell architecture.

TaiyangNews explored metallization and encapsulation for TOPCon technology in depth in our Market Survey on Backsheets and Encapsulation 2022-23. It is available for free download on our website here.