Key takeaways:

Transition from steel to aluminum is reshaping mounting system design, emphasizing recyclability, reduced weight, and durability

K2 Systems’ flat-roof mounting system is moving toward double-sided, ballast-reduced designs to optimize material use and lower BOS costs

Product design updates, such as simplified connectors and pre-assembled components, reflect a broader industry trend toward faster installation and improved safety

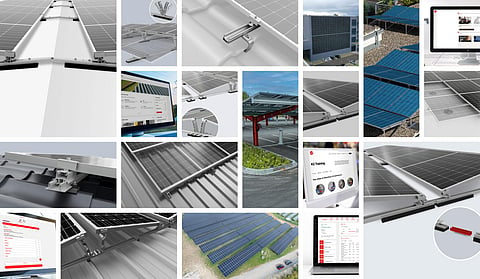

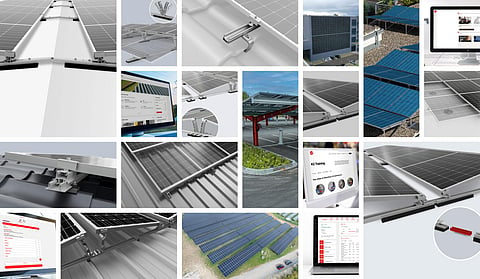

At Intersolar Europe 2025 in Munich, K2 Systems GmbH presented its PV mounting systems, designed in response to shifting industry requirements, design challenges, and regulatory changes.

The company highlighted that developments in mounting systems are being influenced by the construction industry, module manufacturers, the market entry of competitors without structural calculations, and the absence of standardization norms. Meanwhile, new EU regulations are emerging, and product certifications are gaining increasing importance.

There is also a material transition from steel to aluminum underway, driven by factors such as corrosion resistance, sustainability, and design flexibility. It adds that aluminum provides durability without requiring special coatings, is fully recyclable, and allows for more adaptable, lightweight designs that benefit both logistics and assembly.

K2 Systems showcased its innovations in mounting and racking systems for flat roofs, including the Dome system, which has been updated by reducing the wall thickness of the mount and offering a quick snap-in installation. The racking system supports double-sided installation to maximize land use without requiring shading distances between rows. All components are made of aluminum, except for the ramming posts, while stainless steel is used for concrete foundations or in cases where soil acidity is a concern.

Additionally, the company introduced several new products:

An updated Dome system with a pre-assembled design for higher load cases, featuring long-side clamping and tool-free assembly

A single, pre-assembled connector with tool-free and equipotential connection, designed to prevent voltage differences between metallic components and avoid electric shocks

A ridge connector intended to reduce ballast and roof anchor requirements, simplifying module block connections across roof ridges

A load distributor that supports the mounting rail and offers easier installation

A wall mounting system for PV, described as consisting of minimal components and designed for quicker installation

Ground-mount racking system kits for smaller installations

A single-post carport design intended to allow obstacle-free parking. The solution is available in single or double formats, with optional drainage and customization.

.png?w=50&fm=png)