Key takeaways:

KIT’s BiFlow project integrates vanadium redox flow and lithium-ion batteries to provide electricity and heating for a student dormitory

The system incorporates heat exchangers and thermal coupling modules to utilize waste heat alongside electricity storage

According to KIT, the hybrid design supports over 20,000 cycles, a lifetime of 20 years, and could reduce emissions by about 20 tons of CO₂ annually

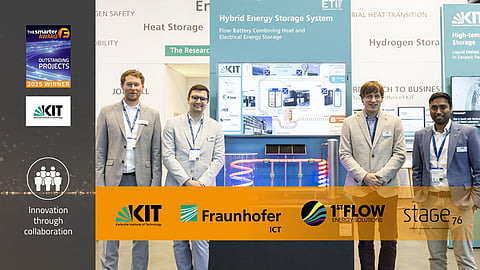

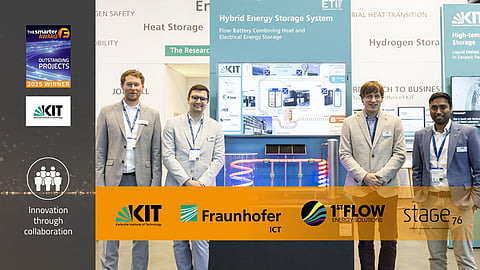

Karlsruhe Institute of Technology’s (KIT) BiFlow project, developed in cooperation with Fraunhofer ICT, 1st Flow Energy Solutions, and STAGE76 – a student dormitory in Bruchsal, Germany – won The smarter E AWARD 2025 in the Outstanding Projects category.

Commissioned in October 2023, BiFlow is a hybrid energy storage system that combines a vanadium redox flow battery (VRFB) with a lithium-ion battery (LIB) to provide electricity and heating for a student dormitory in Bruchsal. The system stores energy generated from local renewable sources.

According to KIT, the purpose of this hybrid storage system is to explore alternatives to lithium-ion technology, given the limited availability of its raw materials. The project integrates the advantages of both VRFB and LIB in a combined system.

In a redox flow battery, energy is stored in liquid electrolytes that flow through electrochemical cells during charge and discharge. Electrolytes containing reduction and oxidation couples, stored in 2 tanks, undergo reversible chemical reactions to store and release energy. These reactions oxidize or reduce the metal ions present in the electrolytes at the positive and negative electrodes, depending on whether the process is charge or discharge. Among the commonly used metal ions for redox flow batteries, such as vanadium, zinc, and iron, the BiFlow project used vanadium-based electrolytes in both tanks with different oxidation states: V2+/V3+ and V4+/V5+.

KIT reports that it investigated the use of sulfuric acid and other additives to stabilize the pentavalent vanadium solution and prevent flocculation of oxides. This approach improved the thermal stability of the vanadium electrolyte, enabling operation between 10°C and 50°C, compared to the standard range of 0°C to 35°C. This modification reduced the battery’s capacity but allowed the electrolyte to store additional heat energy, which could then be used for the building’s heating requirements.

Each tank is equipped with a 35 kW heat exchanger at a ∆T of 20°C. A thermal coupling module (TCM) is used to transfer this heat to and from the VFB. A third heat exchanger, with a nominal power of 75 kW, transfers heat from the TCM to the building’s hot water supply. In cases of excess PV power, the system also includes an electric heating element to heat the VRFB tanks for storage or directly heat the building’s water supply.

KIT mentions that a centralized energy management system (EMS) is designed to manage the hybrid VRFB and LIB system. The EMS helps optimize economic performance, utilize waste heat from the VRFB, reduce battery aging, and increase the self-sufficiency of the overall system.

KIT states that the storage system can sustain more than 20,000 cycles with a lifetime of over 20 years. Additionally, the electrolyte and battery components are described as non-flammable and recyclable. The institute also notes that the system’s power capacity is expected to remain stable over its operational life.

According to KIT, the BiFlow system is projected to reduce up to 20 tons of CO₂ annually and save over €18,000.