The advantages of module products based on M10 (182mm) wafers was the topic for the first day of the TaiyangNews Virtual Conference on High Efficiency Solar Technologies held on Dec 1, 2020. JinkoSolar, one of the three vertically integrated companies that represented the 182 mm based modules wing, has primarily emphasized the advantages of 182 mm modules at the system level compared to 210 mm.

In a presentation titled 182mm Module Boosts System Cost Reduction and Efficiency, JinkoSolar's senior global product manager Leo Yu started his talk pointing at the importance of module design from the LCOE perspective. Being the heart of a PV system, solar module technology is the main key to reduce LCOE. Depending on module technology chosen, parameters such as output power, efficiency, configuration each influence the LCOE. Module efficiency determines land lease and purchase costs, whereas the module type determines operation and maintenance costs. For example, monofacial or bifacial modules, which can use either dual glass or transparent backsheet, impact operation and maintenance costs differently.

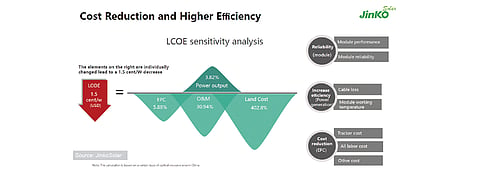

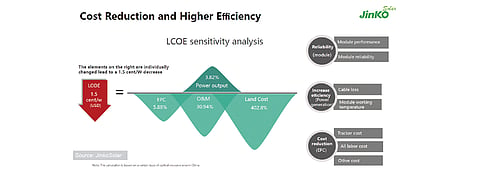

The choice between mono- or bifacial cells also determines the products' power rating. Yu went a step further and provided an LCOE sensitivity analysis to estimate the impacts of different parameters. For example, in order to reduce the LCOE by 0.1 RMB/ W (1.5 US cent/W), module power needs to increase by about 3.82%. The same goal can also be attained by reducing costs in EPC (5.89%), O&M (30.94%) and land cost (402%), a level that is much more difficult to realize. Employing trackers can also boost system power by 10 to 15%, but this correspondingly increases EPC cost, which results in a rather insignificant net benefit, according to JinkoSolar. The main takeaway – choosing the right module is key to reduce cost.

Talking about the compatibility of JinkoSolar's 182 mm based modules, Yu presented a study which compares a 120 MW power plant built with these products compared to one using 210 mm based panels, both in 55-cell and 60-cell configurations. Although 4 mm2 cables can be used for module connection in low irradiance regions when using 182 mm modules, 6 mm2 copper cables that are generally needed for 210 mm panels were considered to aid a fair comparison.

The 182 mm module-based system design showed several advantages. Since the current produced by these modules is relatively low, it reduces cable losses. Such a design does not require overcurrent protection, leading to further savings, emphasized JinkoSolar's Yu. Cable losses for the 182 mm module-based system design amounted to 1.03%, while losses incurred with 210 mm modules were 1.24% and 1.19% in the 55-cell and 60-cell configurations, respectively. Another advantage, claimed by Yu, is that the operating temperature of the modules built with larger 182 mm cells is lower compared to the 210 mm variant. All these benefits were estimated to result in higher power generation of 17,529 MWh over an assumed operation period of 20 years by reducing the cable loss by 0.21%.

Lower losses: JinkoSolar's evaluation of a 120 MW PV power plant built with 182 mm based modules shows lower cable losses than for 210 mm panels.

Another advantage of 182 mm modulesis that they also reduce costs for EPC and BOS, such as trackers. A typical 1P tracker can accommodate a maximum module row length of 100 m. If 182 mm modules are arranged in a 3-string configuration, occupying 96 m, the tracker is very efficiently used. With 210 mm modules spanning either 81.8 m or 86.6 m, utilization is less, according to JinkoSolar. In consequence, 182 mm modules can reduce tracker costs by 0.23 US cents/W, said Lu.

The power density per tracker, enabled by effective utilization of support area by installing 3 strings, is also higher with 182 mm modules. According to JinkoSolar's presentation, the power per tracker with M10 wafer-based modules is 46.5 kW, while it is 41 kW with G12 modules when using a 55-cell layout and 40 kW for modules with 60 cells. M10 wafer-based modules are not only optimally suited for the current generation of trackers, but also new and upcoming designs, said Lu. Even if an upgraded tracker version with 115 m is used or a longer 2P tracker, the total power per single tracker with M10 modules is higher than for G12, Lu pointed out.

More strings, higher power: An M10 module with a higher utilization of tracker support area enables installing 3 strings per tracker, which leads to higher power per tracker, according to JinkoSolar.

Labour is another important cost factor where M10 modules offer savings potential compared to G12 products. Yu estimated that the savings in labour costs for tracker installation, trenching and earth levelling would amount to 800,000 RMB per 120 MW DC power station in China, while there would be even more savings in countries with high labour costs.

In terms of the final BOS cost benefits – which is EPC minus the module price –, a large share of the advantage is coming from the tracker side. The BOS costs for 210 mm are 1.04% to 1.14% higher than for 182 mm, according to Lu. His evaluation of 3 different scenarios for an LCOE analysis – power generation, cable loss and cable loss + module working temperature – showed 182 mm modules have the lowest LCOE in this comparison.

Savings on trackers: The 182 mm module design leads to reduced tracker costs – and as result, lower BOS, according to JinkoSolar

In summary, Yu highlighted that the 182 mm wafer-based Tiger Pro module series is a great product to reduce the LCOE of a PV system. Not only does it come with solid specs in terms of power, efficiency and reliability, but it also enables optimal utilization of trackers, offers good compatibility with mass-produced inverters and fewer cable losses, and poses no risk of running high current.

The text is an excerpt from the TaiyangNews Report High Efficiency Solar: Featuring PERC Modules with M10/182mm Cells Towards Very High Efficiency Products –A Conference Summary, which can be downloaded for free here.

A comprehensive overview on 182 mm cell based modules that boost system cost reduction and efficiency was provided by Leo Yu, Senior Manager of Global Product Management JinkoSolar, during the TaiyangNews High Efficiency Solar Conference; the recording can be viewed here.

.png?w=50&fm=png)