BC cells share similarities with TOPCon but need distinct paste chemistry and firing profiles for simultaneous p- and n-type contacts

Low contact resistance on flat rear surfaces requires optimized glass frit behavior and tuned silver particle distribution

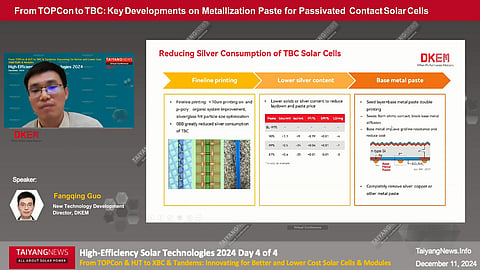

Reducing silver use drives interest in wider fingers, blended-particle pastes, and early copper or base-metal alternatives

With growing PV manufacturer interest in back-contact (BC) technology, its impact on metallization processes is also gaining traction. DKEM provided some insights at a TaiyangNews conference (watch presentation here). From a metallization standpoint, BC, especially the one based on TOPCon, shares some similarities with it, as both involve contacting n-type polysilicon. However, while TOPCon contacts a p+ emitter, BC cells contact a p+ poly layer. Despite these overlaps, BC cells present unique challenges for metallization due to differences in doping levels, surface texture, and passivation schemes. Another key distinction lies in the firing process: TOPCon cells typically fire the front and rear sides at different temperatures, whereas BC cells require simultaneous firing of the p- and n-type contacts, placing additional demands on paste formulation and process control.

BC cell technology presents several metallization challenges, primarily in balancing surface flatness with contact resistance. While a flatter rear surface improves passivation and reduces metal loss, it complicates paste etching and worsens contact resistance – issues more pronounced in BC than in TOPCon. Optimizing the p-poly contact is especially critical, as aluminum cannot be used in this application. Instead, adjustments in glass frit and the composition of silver powder are needed. Improved glass frit flow and silver ion reduction help maintain contact quality, even with thinner p-poly layers aimed at reducing costs and improving bifaciality. For the n-poly side, maintaining a balance between short-circuit current, fill factor, and open-circuit voltage is key. Unlike TOPCon’s split firing process, BC cells require simultaneous firing of both p- and n-poly areas, which impacts paste formulation. DKEM addresses this by first optimizing the p-poly paste, and then tuning the firing profiles and n-poly formulation (see Emitter And Fine-Line Optimization In Metallization).

In terms of printability and silver usage, BC cells still rely on relatively wide finger lines (~30+ μm), unlike TOPCon, which has already moved below 10 μm. Fine-line printing and zero-busbar (ZBB) designs offer paths to reduce silver consumption. DKEM uses a blend of silver particle sizes to balance conductivity and adhesion, achieving paste formulations with reduced silver content (87%-90%) without sacrificing performance. Alternative materials, such as steel and base metal pastes, are also being explored. To further address silver cost and availability, copper pastes are under active development. DKEM is evaluating both base-metal pastes with diffusion barrier layers and pure copper solutions. While promising, the latter requires new equipment and thorough reliability validation to ensure long-term stability at the module level.

The text is an edited excerpt from TaiyangNews’ latest Market Survey on Solar Cell Production Equipment 2025, which can be downloaded for free here.