Module inverter architecture enables panel-level MPPT, allowing each solar module to operate independently

By limiting DC voltage to short panel-level distances and converting power to AC at the module, module inverters significantly reduce fire risk

Installation flexibility and system resilience make module inverters suitable for a wide range of applications, including residential rooftops, BIPV, agri-PV, and public infrastructure

Solar Inverter architectures are increasingly being evaluated not only on efficiency, but also on safety, flexibility, and system-level resilience. During the recent TaiyangNews Advanced Solar Module Applications 2025 Conference, ATMOCE presented a comprehensive strategy for these emerging segments. In a presentation titled ‘Multiple Applications for Solar Module Inverters’ Alec Curry, Product Manager for the DACH region at ATMOCE, discussed how module inverters enable a wide range of installation applications by shifting power conversion from the string level to the panel level.

Curry began by clarifying that ATMOCE operates as a brand focused on module-level inversion. His presentation addressed 3 main themes:

Definition of a module inverter

Reasons for its adoption

Practical applications and system architecture

A module inverter performs DC-to-AC conversion directly at the solar panel. The simplest configuration consists of one inverter per module, forming the smallest technically possible PV system, according to Curry. This architecture enables panel-level MPPT and independent operation of each module.

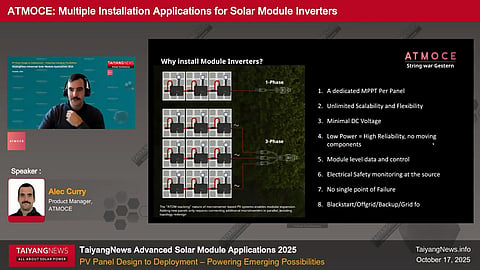

In both single-phase and 3-phase systems, ATMOCE deploys one inverter per panel within each row. As a result, shading, orientation differences, or module mismatches affect only the impacted panel rather than the entire system. According to Curry, this architecture provides a foundation for both performance optimization and installation flexibility.

ATMOCE highlighted scalability as a core advantage of module inverter systems. At the lower end, systems can begin with a single panel and inverter, making them suitable for very small installations, Curry explained. At the upper end, overall system size is constrained primarily by cabling and regulatory limits rather than inverter topology, with installations exceeding 100 kW possible where regulations permit.

Capacity can be added incrementally, given that system expansion does not require reconfiguring strings. Curry mentioned that this flexibility is particularly relevant for distributed and building-integrated PV systems.

He emphasized safety as a key differentiator for module inverters, particularly in European markets where fire risk associated with high-voltage DC cabling is a growing concern. In string inverter systems, increasing module power often leads to long runs of high-voltage DC cabling, which can reach 600-700 V.

In contrast, module inverter systems confine DC voltage to very short distances – typically around 1 m between the panel and inverter – before converting power to AC. With AC voltages in the 230-240 V range, standard protection devices such as residual current devices (RCDs) can be used, reducing fire risk and simplifying compliance with electrical safety standards.

ATMOCE states that its inverters operate below 60 V DC, a threshold at which DC arcing risk is considered negligible. As a result, arc-fault detection devices are not required, simplifying installation and system design, it adds. Module inverters typically operate at lower power levels, in the range of 400-600 W. Curry noted that this reduces thermal and electrical stress on components, supporting a long service life. ATMOCE’s inverters contain no moving parts and are offered with a 25-year warranty.

With panel-level inversion, monitoring and control are performed at the module level. Each inverter can identify abnormal conditions, shut down independently, and isolate a single panel without affecting overall system operation.

The distributed architecture eliminates a single point of failure, preventing a full system shutdown. It allows the system to restart from an individual panel during off-grid operation or grid interruptions. Curry highlighted typical residential scenarios involving chimneys, roof structures, or nearby buildings that cause partial shading. In string inverter systems, shading on one panel can reduce output across the entire string. With module inverters, shading affects only the shaded module.

Typical applications include residential rooftops with multiple orientations, as well as façades, fences, and carports. In these cases, panels face different directions and peak at different times. BIPV was identified as a strong use case due to low DC voltage and electrical safety requirements.

Curry also referenced public infrastructure applications, including PV-covered bike paths and road-integrated PV. In such environments, isolating individual panel faults without affecting the whole system is essential. Agri-PV was highlighted as another key application: low DC voltage reduces risks to livestock and mitigates fire hazards caused by cable damage.

Curry also briefly outlined ATMOCE’s AC-centric system architecture, which integrates module-level inverters with storage, safety functions, and cloud-based monitoring

ATMOCE also offers AC-coupled battery solutions. As feed-in tariffs decline and self-consumption becomes more important, particularly in Europe, battery integration is increasingly relevant. AC-coupled storage allows batteries to be installed alongside ATMOCE systems or retrofitted to other PV architectures, offering flexibility in system design. According to Curry, the architecture also supports smart home integration and load management, enabling higher self-consumption and improved system efficiency.

Module inverters have historically been more expensive but are now cost-competitive with optimized string inverter systems in many applications, he concluded.

TaiyangNews is bringing together the Indian solar PV manufacturing industry for the Solar Technology Conference India 2026(STC.I 2026). To be held on February 5 and 6 in Aerocity, New Delhi, this 2nd edition of the TaiyangNews physical conference will also have banks, investors, and policymakers in attendance. Register for the event here