The defining feature of TOPCon is rear-side passivation using a tunneling oxide and doped polysilicon layer, which reduces recombination losses

Reported cell efficiencies have reached over 26.5% by end-2024, though actual calibrated values may be slightly lower

Front surface passivation, laser-doped selective emitters, and optimized contact formation have become key focus areas for improving fill factor and Voc in commercial lines

More than being based on n-type wafers, the crux of the TOPCon cell structure lies in a true and next-level passivation. Apart from covering the surface passivation requirements, it is also aimed at addressing one main shortcoming associated with prior-art cell structures. Metal contacts formed in the predecessor architectures are highly recombination-active and cause losses. This can be avoided by electronically separating contacts from the absorber by inserting a wider bandgap layer. TOPCon is nothing but adapting this technique to the rear side of the cell (see An Overview Of Trends In Solar Cell & Module Technologies).

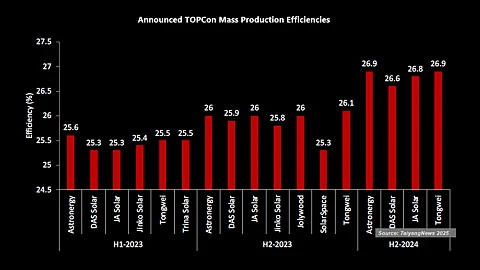

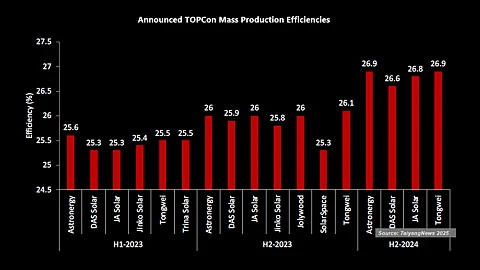

The effort is worth it. It’s astonishing to look at the number of announcements made about efficiency progress by leading manufacturers at several of TaiyangNews' virtual events; the table below provides a nice overview. Several companies had already announced reaching efficiency levels of close to 25.5% by H1-2023, close to 26% by the end of 2023, and beyond the 26.5% level by the end of 2024. However, these high efficiency levels may not be equivalent to international calibrated values. A senior technology leader at a leading production house said there is at least a 0.56% overestimation of efficiency in China, especially due to the calibration method. On the other hand, companies are using the cell efficiency metric only for internal evaluation and benchmarking, and module efficiency is considered the true metric for evaluation. However, ITRPV and CPIA give an estimate for stabilized cell efficiencies. As shown in the graph, CPIA estimates that the average TOPCon cell efficiency has increased from 25.4% in 2024 to 25.7% this year, and is expected to improve by 0.9 percentage points in the next 5 years to 26.6%. A little on the conservative side, ITRPV estimates that the efficiency for 2025 is at 25.5% and will take only 2 years to improve by 0.5 percentage points to reach 26% in 2027, but another 8 years for the next 0.5% absolute improvement (see High-Efficiency TOPCon Modules Built On Rectangular Wafers).

TOPCon Processing

How did the technology get there? The essence of the TOPCon process centers on passivation, specifically focusing on the rear surface engineering of an n-type base wafer. This involves applying an optimal passivation scheme, which includes a nano-scale tunneling oxide layer topped with a polysilicon layer that is then doped. For front surface passivation, TOPCon cells require a layer of aluminum oxide covered by silicon nitride. The rear passivation stack is typically applied using either low-pressure chemical vapor deposition (LPCVD) or plasma-enhanced chemical vapor deposition (PECVD), while some processes also utilize physical vapor deposition (PVD). Additionally, the cell technology incorporates thermal processing steps, such as boron diffusion.

Beyond the rear surface engineering, many leading companies presented their loss analysis simulation results at several conferences hosted by TaiyangNews, which indicate areas of improvement are related to passivation on the front, rear, and bulk. That essentially indicates optimization requirements in the area of recombination in contact and noncontact regions of both p+ as well as n+ surfaces and p+ hole transport regions. In fact, the major losses were coming from the front surface. Thus, the focus naturally shifted to improving the front surface, which includes emitter surface passivation and metal contact recombination. This was followed by some improvements in rear passivation for n+ poly layers. The first line of improvement that nearly every TOPCon manufacturer has taken up is implementing the laser-doped selective emitter to reduce contact resistivity. As it is well known, the application of selective emitters creates a heavily doped metal contact region and a lightly doped non-metal contact region with reduced J0, metal that ultimately helps in increasing fill factor (FF) and Voc. Despite the additional step adding a little to both CapEx and OpEx, the efficiency boost, which was specified to be in the range of 0.15% to 0.3% absolute, as reported by Jolywood and Astronergy in last 2023, lured most of the companies to implement the selective emitter in commercial production. Along with the paste composition, contact optimization was also part and parcel of the whole optimization process.

This text is an excerpt from the TaiyangNews Cell & Module Technology Trends 2025 report, which can be downloaded for free here.