Recycling Approaches For End-of-Life PV Modules

A recent review highlights the growing importance of recycling crystalline silicon PV modules as global end-of-life volumes are expected to rise sharply over the coming decades

Mechanical, thermal, chemical, and hybrid recycling routes each offer distinct advantages and limitations

Hybrid recycling approaches show promise in meeting regulatory recovery targets, but wider deployment will depend on improvements in process efficiency and supportive policy frameworks

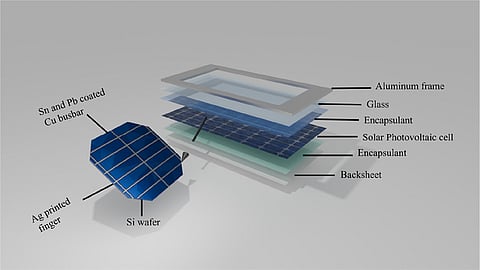

The rapid expansion of global photovoltaic deployment is creating a growing stream of end-of-life modules. By 2050, cumulative PV capacity is projected to exceed 4.5 TW, with associated module waste volumes surpassing 60 million tons. Addressing this challenge through effective recycling of crystalline silicon (c-Si) modules is becoming a key requirement for long-term industry sustainability.

A recent review paper titled ‘Recycling Silicon PV Modules: Advances, Economic Feasibility, and Policy for a Circular Solar Economy’ examines the current state of PV module recycling technologies. The study also assesses their technical performance, economic viability, and relevant policy frameworks.

Mechanical recycling remains the most commonly used route today. It typically achieves recovery rates of 80%-90% for bulk materials such as glass and aluminum. However, shredding and separation often introduce contamination, limiting the recovery of high-value materials such as silver and high-purity silicon. According to the review, the thermal recycling approach can recover silicon with purities reaching up to 99.9999% and achieve silver recovery rates above 90%. Its main drawback, however, is high energy demand, as operating temperatures frequently exceed 500°C.

Silver remains particularly challenging to recover, since it is encapsulated within ethylene vinyl acetate (EVA) layers. Plastics, such as EVA and backsheets, currently lack economically viable recycling routes and are typically used for energy recovery.

Chemical recycling provides the highest selectivity among existing methods. Silver recovery rates above 95% and high levels of EVA removal have been reported. However, hazardous solvents and long processing times limit industrial adoption.

The latest review notes growing interest in hybrid recycling routes that integrate mechanical pretreatment with chemical or thermal processing to address the limitations of standalone methods. According to the analysis, such approaches have achieved material recovery levels exceeding the 85% recovery and 80% reuse targets set under the EU WEEE Directive.

The study estimates potential recycling revenues of around $11-$12 per module, driven primarily by silver and glass recovery.

During the TaiyangNews Solar & Sustainability 2025 Conference, Janett Schmelzer, Head of R&D at Solar Materials, noted that optimized hybrid recycling routes are emerging to enable industrial-scale silver recovery while keeping energy use and costs in check. She highlighted that glass and aluminum account for roughly 65% of module weight, whereas silver makes up less than 0.5% by mass but contributes more than 45% of recoverable value (watch presentation here).

As end-of-life volumes are expected to rise sharply toward 2030, PV recycling is increasingly being viewed not only as an environmental necessity but also as a growing economic opportunity.