UK researchers have fabricated a new kind of BC solar cell design using perovskite

They claim to have achieved stabilized power conversion efficiency of up to 12.8%

Application of roll-to-roll processing ensures high-throughput production and commercial scalability, they argue

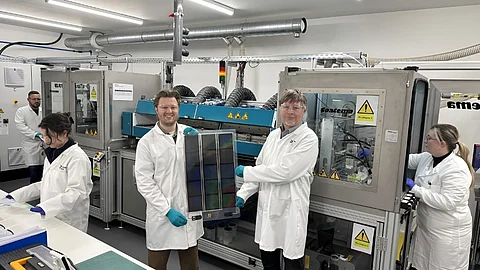

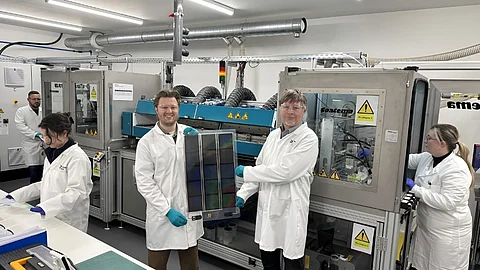

A research partnership between the University of Sheffield in the UK and local solar film producer Power Roll has led to the development of a new type of back contact (BC) solar cell design, using perovskite.

Researchers used a Hard X-ray nanoprobe microscope at Diamond Light Source in Oxfordshire to take detailed images of the solar cells whose traditional structure resembles a sandwich with several layers deposited in a specific order.

Claiming this to be the 1st time such an analysis was carried out, the microscope helped them see hidden problems such as empty spaces, flaws and boundaries between tiny crystals within the semiconductor material.

For its research, the team fabricated a type of BC perovskite solar cell based on 1.5 μm-width grooves that were embossed into a plastic film with opposing walls selectively coated with either n- or p-type contacts. These grooves were then filled with a perovskite precursor solution, using the slot-die coating performed using a roll-to-roll processing technique, that created individual PV devices.

Each groove device is series-connected to its neighbors, creating mini modules composed of up to 362 serially connected grooves. The team claims this process helped it realize a stabilized power conversion efficiency of up to 12.8%.

“Significantly, all techniques used in the processing of groove-based modules, including embossing, are fully compatible with upscaled manufacture, with the titanium and nickel metal contacts used here being significantly cheaper than Indium,” state the researchers.

This way of producing lightweight, flexible solar films can support solar installations for unconventional surfaces along with rooftops where traditional heavy panels cannot be installed, they add.

According to the researchers, “We believe this demonstration of flexible back-contact perovskite solar cell modules manufactured by fully scalable processes that only contains low-cost Earth-abundant materials represents a very promising step toward the commercialization of this technology.”

Researchers plan to further study the fabrication of very narrow and deep grooves using embossing techniques that can further improve the efficiency and stability of such solar cells, and also develop the use of X-ray microscopy in characterizing these materials.

Their research paper titled Back-Contact Perovskite Solar Cell Modules Fabricated via Roll-to-Roll Slot-Die Coating: Scale-Up toward Manufacturing has been published in ACS Applied Energy Materials. It is available for free read on the ACS website.