European thin film solar PV research organization Solliance says encapsulated perovskite solar modules fabricated using industrial processes have been able to pass three lifetime tests. These are the light soak test, the damp-heat test and the thermal cycling test. Joining Solliance in sharing these 'encouraging results' is Eindhoven University of Technology.

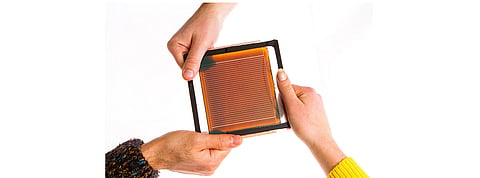

Solliance says the perovskite modules with an aperture area of 100 cm² were prepared on 6×6 inch two glass substrates using industrial processes of sputter coating, slot die coating, atomic layer deposition and laser based interconnection. The modules were glass/glass encapsulated. Initial aperture area efficiency of these modules is above 10%.

Under the light soak test, these modules were exposed to 1,000 hours of continuous illumination at an intensity equal to one sun, 1,000 hours of exposure to relative humidity of 85% and exposure to a temperature of 85 oC under damp-heat test. The thermal cycling test involved 50 thermal cycles from 40 oC to 85 oC.

The two collaborators were satisfied with the outcome of these three tests, "During the light soak test the performance increased in the first 100 hours after which the performance stabilized. After the damp-heat test the perovskite module performance retained 95% of its initial performance, thus within the restricted efficiency loss limit to achieve a successful damp-heat test. The thermal cycling test did not impose any efficiency loss, indicating the excellent stability of the processed modules and the encapsulation strategy to withstand these harsh conditions."

The researchers believe passing these three 'tortuous aging' tests, Solliance and its industrial partners have taken a major step towards commercialization of this novel solar technology. "This will have a major impact on how solar energy can be applied," they claimed.

The two collaborators added that it is the first time this milestone has been cleared with scaled perovskite solar modules prepared by research organizations, and it just pushes perovskite thin film PV technology a step closer to commercialization.

In September 2019, Solliance and MiaSole claimed 23% power conversion efficiency for a perovskite and flexible CIGS tandem cell through process improvement in bottom CIGS cell (see 23% Efficiency For Flexible Perovskite CIGS Cell).

.png?w=50&fm=png)