PECVD is more or less the current state of the art in the regular equipment stream for core layer deposition of heterojunction (HJT) solar cells. An interesting development that has taken place in this segment is that the leading Swiss PV equipment maker Meyer Burger has stopped offering its production equipment including PECVD in the open market. The company, with the longest experience in developing HJT, intends to keep the knowhow in house in order to manufacture solar cells and modules by itself. Archers is one company that is off the radar as an equipment supplier. While Meyer Burger exited, several new companies from different backgrounds, especially from China, have forayed into the supply stream including S.C. New Energy and Maxwell, which are ready with commercial scale tools, while Jinchen is in the process of developing PECVD equipment. PECVD tools designed of other application such as TFT display, for example from Applied Materials were also used in early days of development of HJT. Ideal Energy and PV manufacturer turned into equipment maker GS-Solar are known PECVD vendors that have been continuing their development activity.

Ideal Energy China has intensified its activities in developing PECVD tools for HJT. The company set up a new 7,000 m2 development center in Shanghai, which will be its R&D center. It is currently offering a third generation PECVD reactor for HJT applications that features several improvements. The key development with the latest version is that it can process a larger carrier with 8×8 pockets facilitated by the slightly larger reactor chamber, but it is still a two-stack version. However, the new platform features other improvements, such as increased transport speed and optimized vacuum system, to support higher throughput. The company is using a robotic arm for intra-tool transport. While in the earlier design the vacuum stays open for 8 seconds, it has been reduced to 3 seconds with the latest tool. All these improvements enable the tool to attain a throughput of 5,000 wafers per hour for the M6 wafer size. Another notable improvement associated with the new tool is that it offers the flexibility to process larger wafers. However, the rated capacity of the reactor at 250 MW would not change when opting for larger wafers except when processing 171 mm wafers, in which case the production capacity increases to 280 MW. Honoring an order from an unidentified customer, Ideal Energy is building two third generation tools, while the company has an installed base of 850 MW.

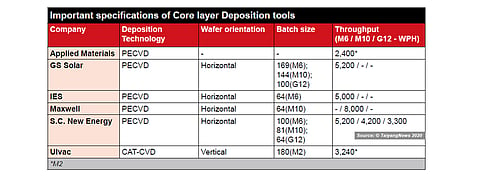

GS-Solar, banking on its thin film PV equipment building background and the experience it gained in establishing a 500 MW fab, has also started offering key deposition equipment for HJT, including PECVD. While the company is reserved regarding the details of its processing equipment, the presentation from Qian Luo at the 3rd SHJT Workshop does provide some insight. The PECVD tool of the company is compatible with multiple wafer sizes—166 mm, 182 mm and 210 mm. The reactor chamber is designed to process 169 wafers of M6 size, 144 pieces of 182 mm in 12 x 12 configuration, or 100 substrates of 210 mm. When processing M6 wafers, the tool has a rated throughput of 5,200 wafers per hour. The capacity difference when changing the wafer size in MW metric is just between 3 to 5% from the given spec of 250 MW. This PECVD system has been selected for Tongwei's HJT mass production project. The below table summarizes the important specs of the PECVD tools from different vendors.

For detailed information of PECVD deposition tools, please check our TaiyangNews report on Heterojunction Solar Technology 2020, which can be downloaded for free here.

.png?w=50&fm=png)