Key takeaways:

Leadmicro reported a 40% throughput increase in LPCVD through redesigned loading, improved carriers, and optimized thermal and gas-flow control

The company’s latest PECVD and ALD systems introduce capacity gains, including 20% higher PECVD throughput and over 50% higher ALD batch capacity

The company showcased process options for BC manufacturing, including half-cell-compatible tools and improved edge-passivation methods for existing lines

At the TaiyangNews Cell & Module Production Equipment & Processing Materials conference, Jerry Liao, CTO of Leadmicro, presented the company’s latest equipment solutions for TOPCon back contact (TBC) solar cells. He began by noting that while most of the industry had completed the transition from PERC to TOPCon by 2024, back-contact (BC) technologies are gradually increasing their share. Leadmicro has therefore shifted its primary development efforts toward TBC, aiming to reduce production barriers for this next-generation architecture. In addition to wet chemical and printing tools, Leadmicro claims to provide the full toolset, including LPCVD, PECVD, ALD, diffusion, and laser processes, required for TBC manufacturing.

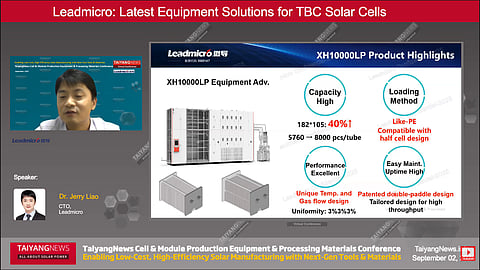

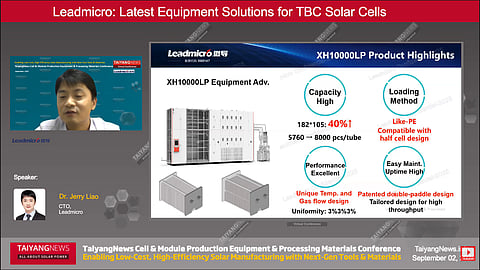

A major part of the presentation focused on the LPCVD process, which is critical for depositing poly-Si layers in TBC cells. Liao explained that TBC cells require 2 LPCVD steps and that the LPCVD poly layers are double the thickness of a traditional TOPCon LPCVD layer. Therefore, TBC’s process cost becomes nearly 4 times that of traditional TOPCon. Leadmicro presented a tool that achieves a 40% increase in throughput through redesigned loading methods, double-paddle carriers, and optimized temperature zones and gas-flow uniformity.

He then described improvements in Leadmicro’s PECVD tools, which are used twice in TBC production to deposit front and rear silicon-nitride layers. The company’s 6th-generation PECVD system increases throughput by about 20% while improving film uniformity. He stated that Leadmicro achieved this by refining gas-flow distribution, temperature control, and the stability of the plasma electrical field, reducing abnormal arcing events by around half compared to previous designs. The presentation also touched on a user-friendly, ‘maintenance-free’, non-cooling electrode method intended to simplify cleanroom operations.

On the ALD side, Liao highlighted why batch-type ALD is expected to dominate BC manufacturing: TBC requires double-side AlOx deposition, which inline ALD cannot support simultaneously. Unlike TOPCon, where manufacturers often deposit on one side only to maintain throughput, BC requires both sides, effectively halving capacity. Leadmicro developed a method to increase single-batch ALD capacity by more than 50%, helping maintain viable throughput rates. Its ALD tools are also claimed to be compatible with different wafer formats, such as M10P and G12R.

Finally, Liao discussed half-cell processing for BC cells, which several manufacturers are adopting to reduce edge-cutting losses. For new BC lines, Leadmicro offers half-cell-compatible LPCVD, PECVD, and ALD systems. For existing full-cell lines, the company provides an ALD-based edge-passivation process capable of processing 40,000 pieces/hour. The second generation of this process eliminates passivation wraparound onto the front surface, which is particularly critical for BC architectures. Liao concluded by summarizing overall capability improvements: LPCVD throughput increased by 40%, PECVD by 20%, and ALD by 50%, all intended to lower production barriers for widespread TBC adoption.