In the world of solar cell manufacturing, TOPCon technology is the current state of the art in mass production. The well-deserved successor of p-type PERC technology with close proximity to PERC cell processing lines paved the path to rapid adoption of the technology in the PV space.

It has quickly attained a mass production cell efficiency of over 26% with further upward potential. Solar manufacturers are evaluating several untapped means to increase TOPCon cell efficiency. At the same time, the technology serves as an effective platform for the next–generation tandem structure to breach the efficiency barriers with crystalline silicon cell structures.

Oscar Zhang, JinkoSolar's deputy general manager of R&D, presented on this very topic at the TaiyangNews annual flagship event, High-Efficiency Solar Technologies 2023 – Today, Tomorrow And Beyond. Zhang provided insights into TOPCon's rapid adoption, development, and the company's future roadmap for the technology to reach more than 27% cell efficiency along with the potential of perovskite-TOPCon tandem cells exceeding 40%.

Landscape of Jinko's TOPCon technology

Speaking about the rapid adoption of TOPCon and its huge potential, Zhang pointed out that market projections by several industry evaluation bodies for TOPCon capacity have started to closely resemble the actuals. This implies that TOPCon product performance and costs have met the industry's expectations. He also presented a 3rd party projection for TOPCon market share of 33% by 2025, growing to 45% by 2030.

Providing JinkoSolar's key figures related to TOPCon technology, Zhang emphasized that the company has 70 to 75 GW of TOPCon cell capacity and realized shipments worth 29.8 GW by the end of Q3-2023, while total module shipments for the period totaled 52.2 GW. He attributes the high shipment volumes to the salient features of JinkoSolar's TOPCon technology-based Tiger Neo modules. Its Tiger Neo modules have power ranges from 460 W to 625 W in 4 different models and efficiency ranges from 22.24% to 22.65%. These products are offered with a yearly degradation of 0.4%, a temperature coefficient of – 0.29%, and a bifaciality of 85%. The module BOM and the cell technology lend themselves well to the modules' performance in reliability tests: degradation of less than 2% in environmental stress tests like DH2000, UV60, and PID192.

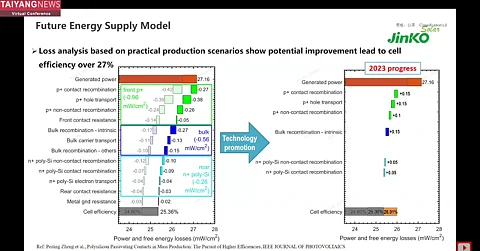

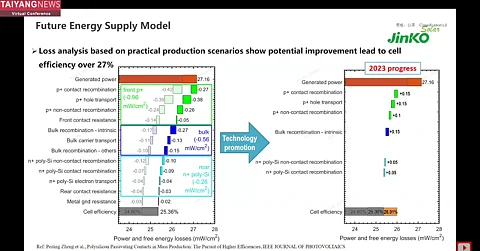

However, the cell is the powerhouse of a module, and improvements at this level are directly reflected at the module level. Speaking about the improvements at the cell level, Zhang presented the so–called 'Future Energy Supply' simulation results. Keeping a cell with 25.36% efficiency as a reference for the simulation of loss analysis showed areas of improvement are related to passivation on the front, rear, and bulk. Implementing these, essentially optimizing recombination in contact and non-contact regions of both p+ as well as n+ surfaces and p+ hole transport regions, over the last 1 year has paid off. By the end of December 2023, these process improvements have resulted in a boost in mass production efficiency of 26.01%, according to Zhang. He further noted that JinkoSolar has recently achieved a lab-scale TOPCon cell efficiency of 26.89% and a module efficiency of 24.76%. These lab performances are just 1 or 2 years away from entering the commercial space, underscores Zhang.

As for the future optimization of the cell structures, JinkoSolar's roadmap includes the following improvements: applying TOPCon structure also on the front (bifacial poly) and optimization of other parameters related to contact formation, absorption in polysilicon layers, passivation and bulk. All of these improvements collectively enable the TOPCon cell to reach an efficiency level of over 27%, showed Zhang, which he expects will be attained in the near future.

Breaking the barriers with tandem

When achieved, this above 27% cell efficiency is close to the practical efficiency limit of TOPCon with its theoretical cap at 28.7%. This necessitates the need to evaluate options to improve cell efficiency further. As it is well known, the PV industry has already started evaluating tandem structures, especially with perovskites.

The good news is TOPCon can be effectively used as the bottom cell of such tandem architectures. Zhang also provided an overview of such TOPCon-perovskites based tandem structure development at JinkoSolar. Such a cell consists of a perovskite top cell interfaced with TCO layer to the TOPCon bottom cell. In November 2023, JinkoSolar achieved a record lab-scale cell efficiency of 32.33% with such a cell of 1cm².

Zhang also provided insights into the latest improvements in the development of the tandem structure. For the perovskite top cell, using new types of materials and additives for surface passivation has improved both the hole and electron transportation layers as well as bulk passivation. In addition, using new additives, JinkoSolar was able to eliminate the hysteresis effect completely, a common concern among perovskite-based tandem cells with regard to accurate estimation of its performance characteristics.

Speaking about the advantages of TOPCon-based perovskites tandem, Zhang emphasized that higher thermal stability of the bottom cell enables high-temperature treatment of the ITO recombination layer, leading to lower resistance and higher transparency. JinkoSolar is further working on optimizing the optical and electrical properties and stability aspects of the TOPCon/perovskite tandem structure, which has a theoretical efficiency limit of 43%.