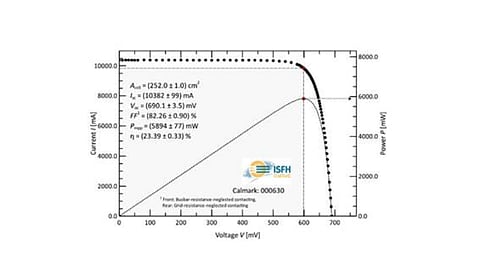

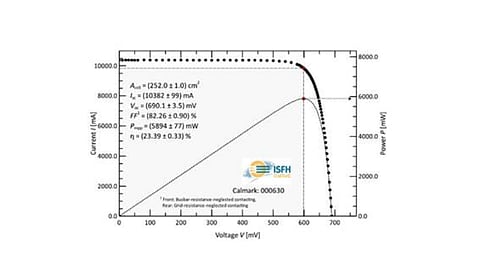

Trina Solar Co., Ltd. claims to have achieved what it calls the highest efficiency of 23.39% for its PERC cell using standard manufacturing equipment. This was announced by the country's State Key Laboratory (SKL) of PV Science and Technology (PVST) that fabricated the PERC cell. Trina says this is the highest efficiency confirmed by an ISO/IEC 17025 certified calibration laboratory for such an industrial cell.

"There is no precisely defined category 'industrial cell' because equipment in mass production evolves over time, and it is difficult to provide evidence of exactly how the reported cell was processed," said Trina Solar's Principal Scientist Dr Pietro P. Altermatt. "Sometimes, higher PERC cell efficiencies are announced, but without stating details about metallization, or whether passivating contacts were used. This makes it difficult to assess progress in the field. This is why we are open about our manufacturing details".

To arrive at this efficiency level, the company used a bifacial PERC cell with 252 cm² area with 9 busbars, calibrated at ISFH CalTec in Germany under full area illumination, with full front metallization taken into account, on a brass chuck contacting the whole rear area.

Trina said that the only difference to mass production for this cell is that during deposition of the antireflection coating, parameters were adjusted as slightly as possible. This helped improved light trapping properties for the cell during calibration in air when encapsulated in a module.

.png?w=50&fm=png)