Wet benches handle saw damage etching and texturing, converting glossy wafer surfaces into low-reflective matte finishes

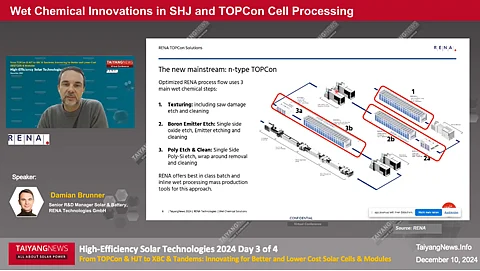

TOPCon typically requires 3 wet-chemical steps, HJT 1 or 2, while BC can involve up to 6

TaiyangNews survey features a total of 81 tools from 14 cell production equipment manufacturers

Wet-chemical processing is the initial step that silicon wafers undergo upon entering solar cell production lines. However, this stage involves multiple specific applications, commonly managed through specialized wet benches. Besides their use at the beginning, wet-chemical solutions also play a role in subsequent cell processing stages, depending on the cell technology. While the primary modus operandi for these wet-chemical tools is etching, their overarching goal is to prepare wafer surfaces for subsequent processes.

Silicon wafers typically enter the cell lines with inherent flaws, such as saw damage, originating from the wafering station. Wet benches eliminate these defects by means of etching in a process called saw damage etching (SDE). This is followed by a highly precise etching process called texturing. The goal here is to transform the wafers' glossy surfaces into matte textures, which significantly reduces reflectivity. Texturing is the heart of the surface preparation station. Wet benches also play an instrumental role in the post-diffusion step. These tools are used in removing glass layers – BSG or PSG – and for executing edge isolation or junction separation (see From Throughput To Advanced Process Optimization).

The wet-chemical process sequences vary significantly depending on the solar cell architecture. For instance, TOPCon cell manufacturing requires 3 steps. Cleaning is another important integral part of these wet-chemical processes. It is gaining increased prominence with cell architectures such as HJT, which typically requires just one wet-chemical treatment. “If gettering is included, HJT also requires pre-cleaning, bringing the total to 2 steps,” says Michael Vees, Sales Director Solar, RENA Technologies GmbH. BC cells demand even more precision in etching operations, presenting complexities greater than HJT but sharing certain similarities with TOPCon processes. Depending on the exact process technology adopted, BC processing involves up to 5 or 6 steps, according to Vees. Tandem solar cells, combining multiple cell technologies, add further complexity and require even more refined wet-chemical procedures, he adds.

In the current TaiyangNews Market Survey on Solar Cell Production Equipment 2025, as in the past, we have categorized the products into 2 subcategories: pre-diffusion wet benches and post-diffusion wet benches. SDE and texturing are part of pre-diffusion, while post-diffusion treatment includes several etching steps, such as doped glass removal, edge isolation, rear side polishing, and polysilicon wraparound removal. We have responses from 14 companies for a total of 81 products in this survey. The majority of these listed products are TOPCon-focused, with a few also for HJT.

RENA’s Vees provides a technology perspective: TOPCon remains the primary focus, with some companies exploring HJT based on their business models and target markets. PERC capacities are declining, though some manufacturers continue to optimize existing lines. Overall, TOPCon has become the benchmark for product improvements among most equipment vendors.

The text is an excerpt from TaiyangNews’ latest Market Survey on Solar Cell Production Equipment 2025, which can be downloaded for free here.

TaiyangNews hosts 2 upcoming conferences in September: the Cell & Module Production Equipment & Processing Materials Conference on September 2, 2025, free registration here, and Solar Made in the USA on September 8, 2025 in Las Vegas: register via RE+ here.