Maxwell offers 2 rotary-table screen printers: MX-XDL and MX-XDLZ, each tailored to different wafer size ranges and production requirements

MX-XDL supports 158 to 220 mm wafers and can be optimized for 100 μm HJT wafers, while MX-XDLZ handles 166 to 230 mm formats

Throughput ranges up to 9,000 wafers/hour for MX-XDL and 7,200 wafers/hour for MX-XDLZ, depending on wafer size and configuration

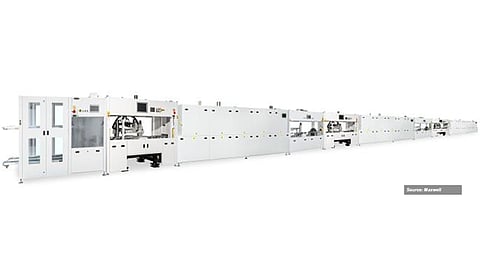

Maxwell Technologies is a Chinese supplier of screen-printing platforms for solar cell manufacturing. The company focuses on rotary-table printing architectures and offers multiple configurations suited to different wafer formats and throughput requirements.

For the TaiyangNews Market Survey on Solar Cell Production Equipment 2025, Maxwell has provided data for 2 tools: MX XDLZ and MX-XDL. It has, however, updated the specs for MX-XDL. Both models use a rotary table design and come with an option of single or dual lanes. The main differentiator between these tools is the wafer size. MX-XDL can handle wafers from 158 mm to 220 mm and 140 μm; however, the printer is optimized to work with 100μm wafers in the case of HJT.

MX-XDLZ is designed to handle wafer sizes from 166 mm to 230 mm. The number of printers integrated into each line also varies: 5 in MX-XDL and 4 in MX-XDLZ. Throughput is the next major difference: MX-XDL now has a throughput of 9,000 wafers per hour with M10 and 7,578 with G12 size and above, while MX-XDLZ is rated at 7,200 and 6,900 wafers per hour, following the same order.