Metallization pastes and laser processes play a decisive role in defining emitter sheet resistance and performance

LECO has become widely adopted in TOPCon production, enabling higher sheet resistance values while decoupling emitter design from metallization

With LECO and compatible pastes, manufacturers now target 300 to 500 Ω/sq, reducing recombination and boosting Voc, while selective emitter designs lose prominence

Emitter formation is a critical yet complex step in solar cell manufacturing, as it requires balancing heavy doping beneath metallization contacts with shallow, lightly doped regions in the open areas. That is why the pastes play a significant role in emitter formation. Emitter sheet resistance is primarily determined by the paste’s ability to establish contact with such an emitter. This is somewhat decoupled by the selective emitter, which is nothing but realizing a deeper and higher concentration of the dopant exactly below the contact regions, while the rest of the open area remains lightly doped. This is typically realized with lasers. Given its undeniable benefit, the selective emitter soon became a standard in the industry. According to the latest edition of the ITRPV roadmap (16th edition) released in May 2025, emitter sheet resistance is about 170 Ω/sq currently, and is expected to increase to 185 Ω/sq in the coming years. The roadmap also included selective emitters in its evaluation. It emphasized that regions between the contacts, typically lowly doped, correspond to a sheet resistance of 170 Ω/sq and would increase to 200 Ω/sq in the coming 10 years (see Developments In Diffusion Furnaces For Emitter Formation).

Meanwhile, the industry has adopted yet another new technology that uses optimized lasers to realize contact firing. This technology, often referred to as laser enhanced contact optimization (LECO), a proprietary name given by its original developer, Cell Engineering (see metallization section for further details), proved to be a game-changer for TOPCon. It is no exaggeration to say that the approach has become a standard, and nearly every TOPCon maker has adopted this technology. While LECO is all about metallization, it also has a considerable impact on emitter formation. This approach completely decouples emitter optimization from the metallization. As a result, emitter sheet resistances increased.

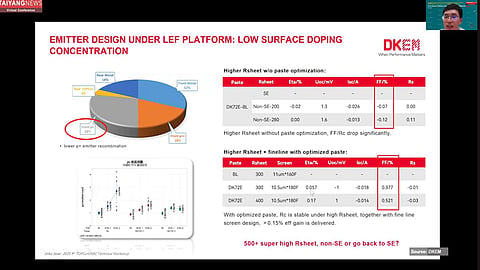

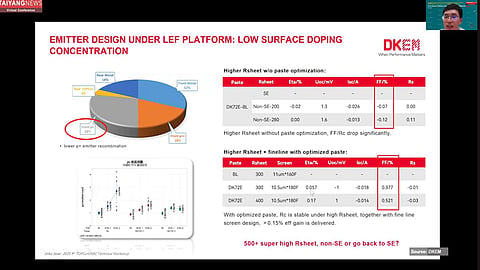

With LECO, most leading PV makers have seen emitter sheet resistance in mass production dramatically increase to about 300 Ω/sq; however, that’s not even the highest. During his presentation titled "Innovative Metallization Pastes Enabling TOPCon Technology Upgrade" at the TaiyangNews Cell & Module Production Equipment and Processing Materials Conference 2024, Fangqing Guo, New Technology Development Director at DKEM, emphasized that a few of the company’s customers have already started working with sheet resistance levels as high as 500 Ω/sq using DKEM’s specially designed laser-enabled firing compatible pastes. These ultra-high sheet resistance emitters enable reduced surface doping and shallower junctions, lowering recombination and increasing open-circuit voltage (Voc). While such high resistance can lead to increased contact resistivity and reduced Fill Factor (FF), DKEM’s pastes, designed for LEF processes, enable efficient contact formation and minimize performance losses, supporting further gains in TOPCon cell efficiency.

Before LECO, the selective emitter was the industry standard. The question now is whether the selective emitter is still required when a LECO-based process is used. There is no straightforward answer; however, most of the industry does not see the need for it. This is further confirmed by a research paper of UNSW's Bram Hoex et al. titled "Higher-Efficiency TOPCon Solar Cells in Mass Production Enabled by Laser-Assisted Firing: Advanced Loss Analysis and Near-Term Efficiency Potential". The study compared conventional selective emitter (SE) designs with homogeneous emitter (HE) structures using laser-assisted firing. Despite lacking SE regions, the approach delivered an absolute efficiency gain of 0.58% and an 11.7 mV increase in Voc, attributed primarily to lower metal-induced recombination at both front and rear contacts.

The text is an edited excerpt from TaiyangNews’ latest Market Survey on Solar Cell Production Equipment 2025, which can be downloaded for free here.