Leadmicro’s ZR5000X2 is its 5th-generation PECVD system for complete rear-side passivation in TOPCon cells

The platform is available in 2 versions: PECVD-only (ZR5000X2-P) and hybrid PEALD + PECVD (ZR5000X2-A) for ultra-thin oxide formation

It supports M10, G12, and 210R wafer formats, processing up to 768 wafers per boat

The system achieves 98 % uptime and 99 % mechanical yield while consolidating all key rear passivation steps into one compact tool

PECVD is a reliable alternative to LPCVD for the application of the rear passivation stack in TOPCon cells. The former comes with several inherent advantages over its rival, and the key benefit is integration, in addition to seamlessly integrating doping of the applied polysilicon layer simultaneously (in situ). Simply put, PECVD can accomplish all the required steps to realize the TOPCon structure on the wafer’s rear side – the application of tunneling oxide and polysilicon layer, and doping the latter. The method also supports relatively low-temperature processing. The technology had a long list of advantages over its key rival during the early days of TOPCon development. PECVD offers faster processing times and higher throughput. Additionally, quartz tube maintenance costs are significantly lower for PECVD, due to lower processing temperature and controlled deposition on the substrate (surpassing the deposition on the process chamber and wafer boats). PECVD is also the first technology to get a grip on wraparound. It allows for precise in-situ doping and film uniformity. However, LPCVD has also evolved, as described above, narrowing its gap to PECVD.

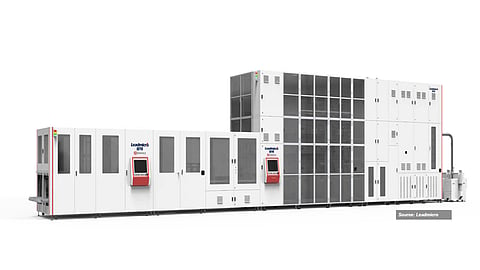

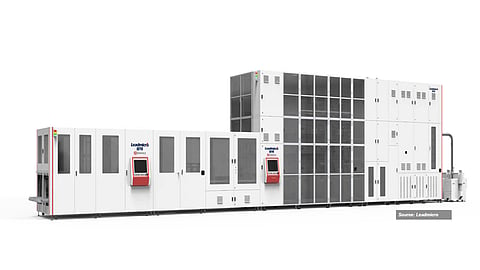

Leadmicro offers 2 types of PECVD tool platforms. Its all-PECVD platform accomplishes all steps using PECVD alone, including the deposition of tunneling oxide and polysilicon and in-situ doping. The company also offers a PEALD + PECVD tool platform that uses PEALD for tunneling oxide formation and PECVD for the application of polysilicon and subsequent doping. The purpose of using ALD is to realize a very conformal coating, a signature outcome of ALD, which enables the application of very thin tunneling oxide layers that favor efficiency. Leadmicro’s ZR 5000 series represents its 5th generation PECVD platform, designed to perform all key rear-side passivation steps for TOPCon solar cells within a single tool. The system integrates PECVD-based tunnel oxide deposition, intrinsic polysilicon, in-situ doped polysilicon, and masking layer formation in one inline batch configuration (see Deposition Technologies For Passivation In Advanced Solar Cells).

Its 5th-generation ZR5000X2 platform is available in 2 configurations. ZR5000X2-P represents the PECVD platform, which performs PECVD-based tunnel oxide and poly-Si deposition in a single tube using direct plasma.

ZR5000X2-A integrates PEALD-based tunnel oxide formation with PECVD for poly-Si deposition. Both tools support M10, G12, and 210R wafer formats, processing up to 768 wafers per graphite boat. The throughput ranges from 6,500 to 7,100 wafers per hour for M10 wafers, depending on the configuration. These systems boast an uptime of 98% and a mechanical yield of 99%, while simplifying line architecture by integrating all core rear passivation steps into one tool. Leadmicro claims that out of the 828 GW of PV production capacity built on TOPCon architecture, 55% uses PECVD-based passivation.