PECVD remains the primary method for depositing silicon nitride and aluminum oxide layers used in BSF and PERC cells

LPCVD and ALD are widely adopted in TOPCon for tunnel oxide and poly-Si layers, while PVD is regaining traction in Europe

BC and perovskite cells demand ultrathin, highly uniform passivation films deposited using hybrid or spatial ALD processes

After outlining the fundamentals of passivation, this section focuses on the deposition technologies used to form passivation layers in different solar cell architectures. Getting into the details of the passivation schemes and the required production equipment, they vary significantly for different cell architectures. Silicon nitride has been the most reliable material for the sunny side of a BSF cell, and the PECVD method has been the state of the art for its application as both an antireflective and a front surface passivation film. The material of choice for rear passivation for PERC is aluminum oxide. As for the deposition of this material, one of the 2 mainstream technologies available is again PECVD, which has been in use for silicon nitride deposition for years ( see Passivation – A Key Differentiator Across Solar Cell Technologies).

The other is atomic layer deposition (ALD), which has its roots in the semiconductor industry. Regardless of the method, a protective capping layer is a prerequisite, which is again silicon nitride deposited with PECVD. TOPCon involves the growth of interfacial silicon oxide and deposition of intrinsic polycrystalline silicon layers, the latter of which is subsequently doped. The tunneling oxide can be grown thermally or as part of any other deposition methods used for polysilicon deposition, which is the heart of the TOPCon process. Well-known deposition methods such as LPCVD and PECVD are used to realize this key step in TOPCon processing, either alone or in combination with ALD. While PVD has been used here with a stagnant number of followers, it now gets a fresh push from the European equipment wing.

When it comes to BC, the concept remains the same as that of the main architecture adapted – TOPCon or HJT. However, since the structure moves all the contacts to the rear side, the passivation requirements are even more stringent, also increasing the complexity in realizing them. The technology demands full-surface passivation with minimal recombination. This is typically achieved using a combination of tunnel oxide and doped polycrystalline silicon layers, deposited via LPCVD, PECVD, ALD, or advanced hybrid methods.

Solar cells based on perovskite, the buzzword in today's PV cell/module manufacturing world, not only require ultrathin passivation layers, but they also require precise and pin-hole free-electron and hole transport layers. Since the perovskite structure differs across manufacturers, several methods are in the race. For electron transport layer deposition, ALD is gaining traction due to its ability to deposit thin, conformal films. One company has also developed spatial ALD. In addition, other vapor deposition technologies, such as PVD sputtering and thermal evaporation, are also optimized for the application of the electron transport layer.

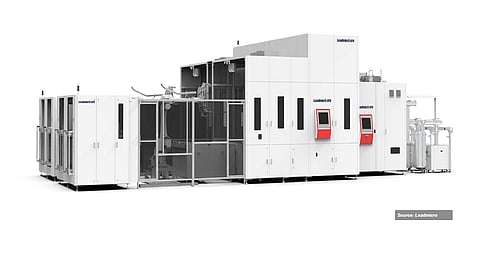

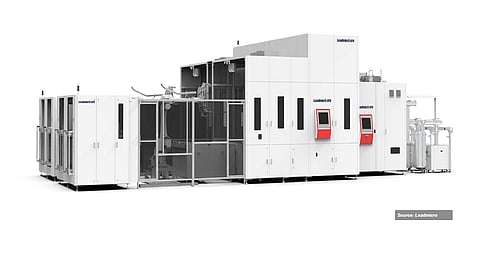

The TaiyangNews Market Survey on Solar Cell Production Equipment 2025 includes a section on passivation that details the different deposition techniques, including LPCVD, PECVD, ALD, and PVD, in the context of TOPCon. This is because for HJT, passivation is part of the core layer deposition, and the tool set is completely different. For BC, the respective deposition tools require tweaking, but since the technology is considered proprietary, the production tool suppliers have not listed the detailed specifications of the tools used for BC.

The text is an edited excerpt from TaiyangNews’ latest Market Survey on Solar Cell Production Equipment 2025, which can be downloaded for free here.