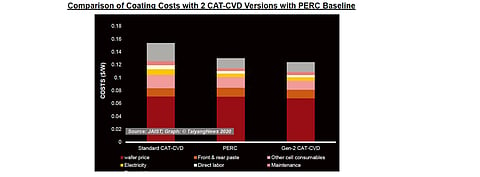

In HJT solar cell processing, while every step is important and ultimately contributes to the final cell performance, core layer deposition attracts the utmost attention. That's because, as discussed in our earlier article The Core Of HJT, the core layer not only governs the performance of the HJT structure, it also strongly influences costs. While PECVD is currently the mainstream technology for depositing the core layers, CAT-CVD is another well known route. The technology also carries the legacy of being used by the pioneer of HJT, Panasonic. Japan's Ulvac has been the main supplier of such CAT-CVD tools. While the Cat-CVD was adopted by several companies during the development phase, the technology has not won any bids for large-scale HJT production plans. While CAT-CVD has lower manufacturing costs, as shown by Hideki Matsumura from JAIST at the 3rd SHJ Workshop of Jülich Research Center, the technology suffers from a few limitations such as not handling-automation friendly, limited scope for throughput enhancement and the design leads higher breakages.

Addressing some of the shortcomings of traditional CAT-CVD reactors, Matsumura presented a second generation CAT-CVD reactor design at the SHJ Workshop. Estimating CapEx—the major contributor for high costs of HJT—at close to $0.03/W compared to that of PERC at $0.015, Matsumura emphasized the production costs for HJT can be reduced by using CAT-CVD for core layer deposition. In terms of performance, the presentation showed that proper cleaning of the wafer surface can result in better performance of amorphous silicon layers deposited with Cat-CVD compared to PECVD. The technology enables placing carriers on both sides of the catalyzer without affecting the quality of the deposited film. As for debottlenecking the productivity further, Matsumura emphasizes that CAT-CVD supports adding more number of process trays (in multiples of two) to increase the throughput proportionately. Higher utilization rate of processing gases, reduced cleaning cycles, free hand to alter the pressure and reducing the possibility of power generation are the other highlighted advantages of the technology. Matsumura proposed that a cluster type CAT-CVD design using four parallel trays has the potential to increase the throughput to 8,640 wafers per hour, which would reduce the overall production costs for HJT to the level of PERC.

For detailed analysis on CAT-CVD and Core layer deposition tools used for HJT production, please download and read TaiyangNews report on Heterojunction Solar Technology 2020, which can be downloaded for free here.