Key takeaways:

Solar Materials plans to scale its automated recycling capacity to 35,000 tons per year by 2026

Solar waste in Europe is expected to increase sharply by 2030, creating both environmental and material-recovery challenges

Silver and silicon account for most of a module’s material value, but extracting them efficiently remains the main technical bottleneck

As the early utility and rooftop installations approach the end of their operating life, recycling volumes are set to rise sharply. Sustainability discussions also often focus on the end-of-life management of PV modules. At the TaiyangNews Solar & Sustainability conference 2025, Janett Schmelzer, Head of R&D at Solar Materials, spoke about the emerging challenge of PV module recycling and how the industry is preparing for the first large wave of decommissioned solar panels.

According to Schmelzer, annual solar waste in Europe alone is expected to grow 20-fold by 2030. This presents not only an environmental obligation, but also a material opportunity. PV modules contain strategic raw materials, most importantly silver and silicon, whose combined market value runs into billions of euros. Recovering these materials at scale could play an important role in reducing Europe’s dependence on imports while strengthening a circular solar economy.

Solar Materials was founded in Magdeburg in 2021 and now operates what Schmelzer described as Europe’s most advanced crystalline silicon module recycling facility, with a current capacity of about 7,000 tons per year. The company processes modules from a wide range of sources: hail-damaged plants, storm-damaged modules, repowering projects, production rejects, and degraded modules. These modules arrive stacked on pallets, which already creates a logistical challenge due to the weight and volume of framed glass modules. Schmelzer pointed out that recyclers are always working 10-15 years behind manufacturing volumes, and a much larger wave of end-of-life modules is now approaching.

Inside a typical module, around 65% of the weight comes from glass and aluminum, which are relatively easy to recycle. However, although silver makes up less than 0.5% of the total weight, it accounts for more than 45% of the material value. Silicon is the second most important component, but only if its purity can be preserved. Most industrial recyclers today can only produce silicon with about 95% purity, which limits its reuse to alloys and chemicals. Solar Materials’ goal is to achieve solar-grade silicon purity of 99.9999% (6N), enabling recovered silicon to be reused directly in new cells.

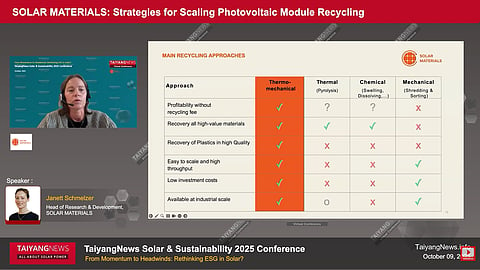

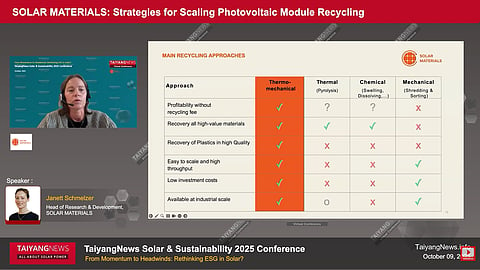

The real technical bottleneck lies in accessing these materials. Silver is encapsulated inside EVA layers and backsheets, making it difficult to extract efficiently. Current recycling routes rely on combinations of thermal, chemical, and mechanical processes, but no single method meets all industrial requirements: profitability without recycling fees, high-value material recovery, plastic reuse, scalability, low investment cost, and industrial throughput. Solar Materials’ approach has been to selectively combine the thermal and mechanical processes, with a strong focus on economically viable silver recovery.

Silicon recovery is improving but remains a work in progress. Mechanical separation methods are being refined to avoid contamination, while chemical treatments are being developed in cooperation with research partners. Schmelzer noted that newer cell architectures, such as TOPCon and heterojunction, may simplify purification in the future, but today’s crystalline silicon modules still pose a major challenge for high-purity silicon recovery.

Plastics remain the most difficult fraction. EVA and backsheets account for about 10% of each module, but currently have no profitable recycling route and are typically incinerated for energy recovery. Their complex composition, often containing additives and fluorinated compounds, makes mechanical recycling difficult and sometimes hazardous. Schmelzer says Solar Materials is actively exploring new processing routes with research institutions to find a safe and scalable solution.

Despite these challenges, Solar Materials claims to be recovering around 98% of module materials. Aluminum frames go back into the aluminum industry, copper cables return to electrical manufacturing, glass is reused as flat glass, silver is refined into fine silver, and silicon is reused as industrial feedstock. Recycled materials save roughly 80% of the energy and CO₂ emissions compared to primary raw materials.

Solar Materials’ first industrial recycling line is already operational and fully automated. By 2026, the company plans to expand capacity 5-fold from 7,000 to 35,000 tons per year, with its first international facility planned in Italy. The expansion would allow recycling of up to 350,000 modules annually and could set a new benchmark for industrial-scale PV recycling in Europe, concluded Schmelzer.

The full video presentation, titled Strategies for Scaling Photovoltaic Module Recycling, can be accessed here.