Conventional ALD offers excellent film quality for perovskite transport and passivation layers, but is constrained by low throughput

Ideal Deposition’s spatial ALD separates precursor flows spatially, eliminating purge steps and significantly increasing deposition rates

SALD-deposited SnO₂ and Al₂O₃ films demonstrate high uniformity, optical transparency, and improved moisture resistance

Perovskites, the latest buzzword in the industry, require deposition techniques that support the application of precise, dense, pinhole-free, and conformal films. ALD ticks all these boxes. This deposition technology is widely recognized for its ability to deposit ultraprecise films at the atomic level, making it an attractive choice for fabricating perovskite solar cells. ALD is known to have been used for fabricating electron and hole transport layers, such as tin oxide (SnO₂), zinc oxide (ZnO), nickel oxide (NiO), and ultrathin aluminum oxide passivation layers. However, ALD's long processing times significantly limit throughput, making it less viable for mass production.

As an alternative, Ideal Deposition has developed a spatial ALD system. Jun Wang, process technology manager at Ideal Deposition, presented the details of the system at the TaiyangNews High-Efficiency Solar Technology Conference in December 2024. The system improves deposition efficiency spatially, rather than temporally, separating the precursor gases. Unlike conventional ALD, SALD does not require purging steps, dramatically increasing the deposition rate by several orders of magnitude.

In SALD, precursors and inert gases continuously flow toward the substrate through a multi-channel showerhead. The substrate moves laterally under the showerhead, sequentially encountering the precursors. Inert gas curtains between the precursor flows prevent intermixing and direct the precursor molecules toward the exhaust system.

The technology, however, is not new. SoLayTech and Levitec, 2 Dutch companies, have developed such spatial ALD tools for the application of aluminum oxide. However, they were not successful in rolling out the technology to the mainstream, at least for solar.

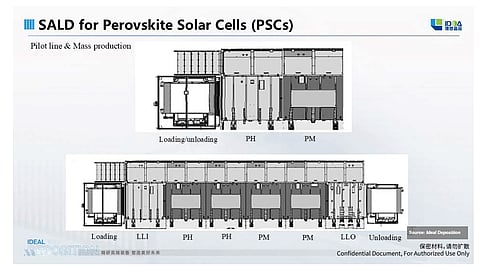

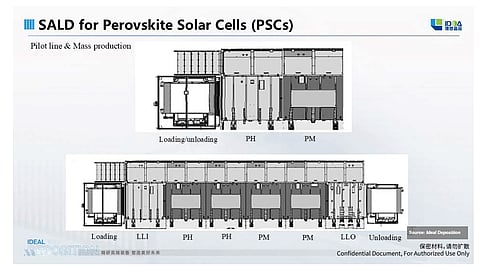

Ideal Deposition has developed dedicated SALD tools tailored for each stage of perovskite solar cell development and production, according to Wang. The company’s R&D platform can handle substrates up to 300 × 400 mm, achieving coating non-uniformity of less than 3% and depositing 20 nm films in just 18 minutes. The pilot-scale system supports large substrates of up to 1.2 × 2.4 m with non-uniformity of less than 5%. The mass production tool features modular, multi-chamber configurations designed for scalable, high-throughput manufacturing. These systems support various substrates, including glass, silicon wafers, and flexible materials, and operate across a wide temperature range (80°C to 300°C), offering broad compatibility with perovskite materials and transport layers (see Ideal Deposition: Spatial Atomic Layer Growth In Perovskite Cell Fabrication).

SALD-deposited films demonstrated the process’s ability to meet the stringent requirements for PSC stability and efficiency, according to Wang. Tin oxide films, for example, show linear thickness growth per cycle (~0.1 nm) and high transmittance (~96% for 20 nm layers). Moreover, perovskite layers coated with SALD-grown SnO₂ and Al₂O₃ films exhibit enhanced moisture resistance. Stability tests confirm that these layers significantly mitigate water ingress, with no visible degradation after immersion in water for several minutes. Across both lab-scale and large-area substrates, SALD has achieved film thickness uniformity within 2% to 4%, underscoring its reliability and scalability. Counting on the combination of speed, precision, and protective film quality positions, Ideal Deposition promoted its SALD as a promising deposition technique for next-generation perovskite tandem solar cells.

The text is an edited excerpt from TaiyangNews’ latest Market Survey on Solar Cell Production Equipment 2025, which can be downloaded for free here.