Key takeaways:

According to Fraunhofer ISE, UVID in TOPCon modules can be influenced by metastability effects, making post-stress stabilization through light soaking essential

Current mechanical load tests may not fully replicate real-world glass fracture patterns in large-format modules, prompting further investigation into stress conditions and test protocols

Dark storage can temporarily reduce module power, affecting calibration references and certain field diagnostics, though it has a limited impact on long-term energy yield

Reliability testing plays an important role in understanding and predicting the performance of a PV module. TOPCon, as the industry’s workhorse, even presents certain issues out in the field. The testing and calibration laboratory at Fraunhofer ISE has addressed some of the common issues faced with installed TOPCon modules.

At the TaiyangNews Reliable PV Module Design 2025 Conference, Ingrid Haedrich from Fraunhofer ISE shared recent findings from the institute’s testing and calibration laboratories. Her presentation focused on 3 topics currently drawing attention in the industry: UV-induced degradation (UVID) in TOPCon modules, glass breakage in large-format panels, and storage-related metastability effects that influence power measurements.

Fraunhofer ISE operates both a calibration laboratory and an accredited test lab for PV modules. With measurement uncertainty for maximum power of around 1.1% and more than 15 years of historical data, the institute is well positioned to detect long-term trends and subtle deviations. According to Haedrich, their work also focuses on root-cause analysis and detailed understanding of degradation mechanisms rather than simply certifying modules against standards.

One of the key observations over the past 2 years concerns UVID in TOPCon modules. In standard stress-test sequences, Fraunhofer ISE observed an unusual pattern: modules would degrade after UV exposure but then partially recover. This was later linked to metastability effects driven by dark storage. The industry now recognizes that after UV stress testing, modules must be stabilized, typically through light soaking, before final measurements are taken. Fraunhofer has since adapted its internal testing procedures to include light soaking after stress tests to ensure consistent results.

The question, however, remains: how well does indoor UV testing correlate with actual field performance? Fraunhofer ISE compared indoor UV exposure at 60 kWh with outdoor exposure across 3 different test sites, including both PERC and TOPCon modules. The results showed that indoor tests slightly overestimate UV degradation compared to field conditions. The difference is not dramatic, but it raises questions about spectral differences, UV dosage assumptions, and the role of temperature in outdoor environments. The team continues to investigate whether indoor test protocols need refinement or whether correlation factors should be adjusted.

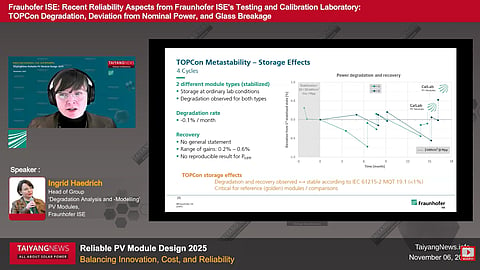

Haedrich also addressed the so-called dark storage effect. In the absence of light, modules can temporarily lose power, which is quickly recovered when exposed to sunlight again. In one experiment, modules installed in the field for a year were turned face down for several hours. A power drop of around 0.6% was observed, which recovered rapidly under sunlight. Importantly, this short-term effect does not significantly influence daily energy yield. However, it can affect nighttime electroluminescence (EL) drone inspections, where modules may appear darker due to temporary power loss after prolonged darkness. This has led to some confusion in field diagnostics.

The second major topic was glass breakage in large-format modules. As the module size increases and glass thickness decreases (2 mm or below), the industry is seeing fracture patterns in the field that are not well reproduced by current mechanical load tests under IEC 61215. In the laboratory, mechanical load tests typically produce fine, chaotic crack patterns under high uniform loads (2,400 Pa). In contrast, field failures often show singular, round-shaped fractures originating from surface stress rather than edge loading. Fraunhofer ISE’s investigations suggest that current standardized tests may not fully represent real-world stress conditions. Simulations using lower, inhomogeneous loads more closely resemble the fracture patterns observed in the field. Another contributing factor may be long-term sagging between frames in large modules, which introduces continuous pre-stress into the glass. Finite element simulations indicate that stress lines caused by sagging correlate with later fracture lines observed in practice.

Finally, Haedrich discussed metastability and storage effects in out-of-the-box TOPCon modules, separate from UV exposure. Fraunhofer ISE measured modules for 16 months under normal laboratory storage conditions, where lighting varies between light and dark phases. It observed an average monthly degradation of around 0.1% due to dark storage effects, with cumulative losses reaching about 0.6% before recovery through light soaking. This has practical implications for ‘golden modules’ used for calibration. If such reference modules are stored in darkness for extended periods without re-stabilization, measurement deviations may occur when they are returned to the manufacturer for line calibration.

It can be concluded that while the effects, such as UVID, dark storage degradation, and glass breakage issues, are better understood, they also highlight the need to continuously adapt testing procedures to evolving module designs. Ingrid Haedrich’s full presentation titled Reliability Aspects from Fraunhofer ISE’s Testing & Calibration Lab can be accessed here.