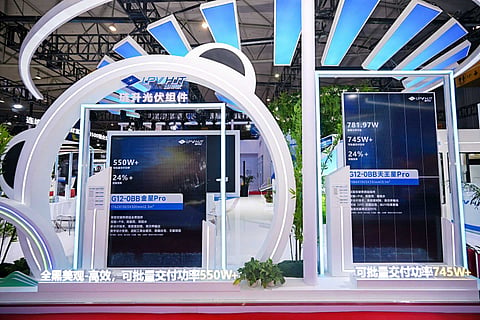

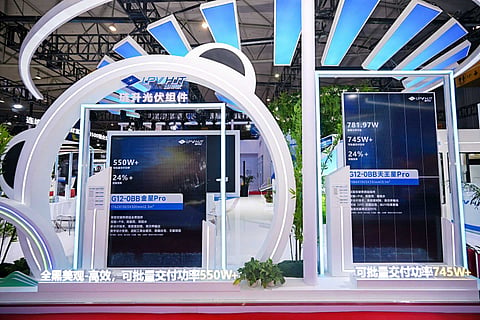

Leascend PV’s Uranus Pro and Venus Pro series modules are rated for a power output of up to 745 W and 550 W, respectively

While the former large-sized bifacial module is suitable for utility, the latter, with smaller dimensions, can be used in rooftop applications

Both modules are currently in mass production at the company’s Meishan-based factory and are commercially available

China’s Leascend Photovoltaic Technology Co., Ltd. (Leascend PV), a heterojunction (HJT) cell and module manufacturer, recently launched its latest PV modules, developed for all application scenarios at the 8th China International Photovoltaic and Energy Storage Industry Conference 2025.

The 2 showcased products, Uranus Pro and Venus Pro, feature a multi-split cell design. These modules consist of G12-size busbarless (ZBB) cells, each cut into 4 equal parts along the length. While the former features 276 cells (¼ cut cells) and measures 2,384 × 1,303 × 33 mm, the latter is smaller at 1,762 × 1,303 × 33 mm and is equipped with 192 cells (¼ cut cells). The images of these modules show no cell-to-cell gaps; however, the company’s press release didn’t disclose whether it adopts zero or negative-gap architecture. The company says that this ‘high-density packaging’ with increased active cell area enhances Uranus Pro’s mass-produced power output and efficiency compared to its predecessor, Uranus G12-0BB module. Compared to the previous rating of 740 W and 23.82% efficiency, the newly launched large-size double-glass bifacial module reaches up to 745 W of power output and 24% efficiency. Its bifaciality reaches up to 95%, making it suitable for ground-mounted utility projects. The company states that the smaller-sized double-glass monofacial all-black counterpart is developed for residential and commercial & industrial (C&I) rooftop applications. It boasts a power output of up to 550 W and an efficiency of up to 24%, in conjunction with an aesthetically pleasing appearance.

In terms of long-term product and performance reliability, these modules use PIB-based edge sealant, a highly impermeable elastomer, along the edges of the PV laminate, dual glass, and frames for protection against humidity and water ingress. Given the HJT cells’ high susceptibility to UV-induced degradation (UVID), the bifacial model includes a front-side light conversion film (LCF) that converts incident UV light into visible sunlight.

During his keynote speech, Tang Anmin, R&D Director of Leascend PV, briefly shared key features of the company’s current HJT technology being mass-produced at the company’s 8 GW Meishan factory. According to Anmin, these cells use thinner silicon wafers, adopt silver-coated copper metallization paste, and eliminate cell interconnection busbars with a ZBB layout. Without quantifying the magnitude, the company says these attributes reduce mass-production costs compared to its earlier version. He also shared an update on the company’s technological progress in developing perovskite tandem cell technology, achieving up to 32.99% efficiency in laboratory settings.