Shenzhen S.C New Energy has secured a 5 GW TOPCon turnkey project in Türkiye, with 3 GW delivered by the end of H2 2025

The company is expanding its localized service capabilities, including regional teams and on-site technical specialists to support installation, commissioning, and ramp-up

It states that TOPCon remains the primary driver of new equipment demand, supported by tube-based LPCVD platforms, lower capital intensity, and a more mature supply chain

As solar cell manufacturing expands beyond China, equipment suppliers are increasingly required to support overseas projects with not only process technology but also long-term local service and commissioning capabilities. A leading Solar equipment manufacturer Shenzhen S.C New Energy has revealed an expanded overseas strategy focused on turnkey project delivery and after-sales operations.

Shenzhen S.C said it has upgraded its globalization approach through a next-generation overseas ‘technology plus service’ model. Under this framework, the company is building localized teams and regional service infrastructure while providing lifecycle support spanning installation, commissioning, and production ramp-up.

The company reported the launch of a vertical LPCVD system designed to increase production capacity by up to 2.5x and extending tube furnace service life to up to 2 years. According to the company, the platform supports higher-throughput TOPCon manufacturing with improved film uniformity, yield stability, and mass-production consistency.

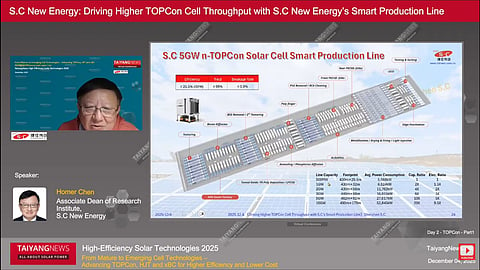

At the TaiyangNews High Efficiency Solar Technologies Conference held in December 2025, Homer Chen, Associate Dean of the Research Institute at Shenzhen S.C New Energy, emphasized tube-based processing platforms as central to the company’s TOPCon roadmap.

He noted that Shenzhen S.C’s experience with deployed production lines has directly informed the design of current smart production lines. These smart lines are offered in modular configurations starting at 500 MW and scalable to multi-GW capacities, enabling flexible deployment across different project sizes and markets.

The company expanded its overseas project portfolio by securing a 5 GW TOPCon turnkey contract in Türkiye during H2 2025, with 3 GW delivered by the end of the year. Over the same period, it secured multiple turnkey projects in the United States, including 6 GW PERC, 3 GW TOPCon, and 1 GW HJT production lines.

Among the clientele for these projects are ES Foundry, Boway, and SolarSpace. According to the company, full commissioning and production ramp-up are scheduled for completion in 2026.

Shenzhen S.C has expanded its international service footprint to support these overseas deployments. It operates through subsidiaries across Asia and the United States and maintains manufacturing bases in Japan and Malaysia. The company stated that it has deployed more than 30 technical specialists to strengthen local service and after-sales support in the US.

Providing background on its expansion, Shenzhen S.C stated that it began international activities in 2010, exporting its first equipment to Japan. It adds that it has supplied solar cell manufacturing tools, process technologies, and full-line turnkey solutions across Southeast Asia, South Asia, Africa, and the Americas over the past 15 years.

In terms of capacity, its cumulative delivered cell lines now exceed 100 GW, with turnkey lines accounting for more than 80 GW, and span multiple cell technologies, including multicrystalline, PERC, TOPCon, HJT, and perovskite. Chen noted during the conference that TOPCon currently dominates new-equipment demand, driven by lower capital intensity and a more mature supply chain than other n-type technologies.

The company now operates across 22 countries, including the United States, Japan, South Korea, Türkiye, Oman, and Egypt. It adds that it continues to focus on supporting multiple cell technology routes while providing turnkey solutions as solar manufacturing globalizes.

Homer Chen also participated in the TaiyangNews Solar Cell Production Equipment Survey. His presentation, titled Unlocking Optimization Potential in TOPCon, covered manufacturing steps ranging from wet-chemical processing to metallization (watch the presentation here).