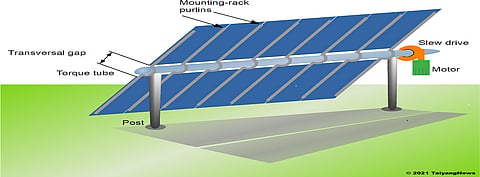

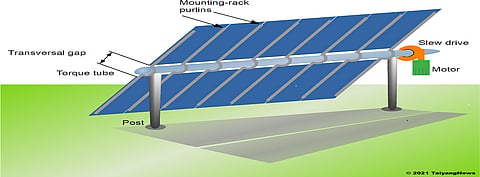

Horizontal single-axis trackers employ various mechanical and electrical components. The electrical components consist mainly of motors, sensors, controllers, and actuators, while the axis or torque tube, the tracker mount, fasteners and clamps belong to the mechanical components. This article provides an overview on the key components of HSAT trackers.

The torque tube or axis is an important component of a HSAT system. All PV modules are connected to the torque tube which take care for the tracking of the suns' path of all modules simultaneously. The torque tube can be either round or quadratic. The axis has to support heavy and dynamic loads; thus, the choice of material is crucial, typically galvanized steel is used. The axis is driven by one or several motors using different approaches, such as slew drives. The reflectivity of the torque tube is important if bifacial modules are employed.

The tracker mount is the skeletal metal construction on which the solar modules are placed. In case of bifacial modules, it is favourable if the tracker mount has no crossbeams to avoid shadowing.

Tracker manufacturers offer different mounting options for the modules: one-in-portrait (1P) or two-in-portrait (2P) or two to four in landscape (horizontal) orientation (2H or 4H) on the tracker rack. Of the 17 HSAT suppliers listed in TaiyangNews survey, four companies offer only 1P and another four only 2P trackers, while two companies offer 1P, 2P and 3H systems and only 1 company offers 3P and 6H systems. For bifacial systems the torque tube is mostly placed with a bigger gap between the modules in a 2P configuration. Some companies offer 1P tracker architecture also for bifacial modules and modify the torque tube geometry and reflectivity.

The core of a solar tracker is its driving mechanism and its ability to function up to the maximum operational wind speed and prevent damages under all operating conditions. The driving mechanism typically consists of a motor, a gearbox to transform motor speed in torque and a drive, which provides rotary or linear motion to turn the tracker axis.

Either alternate-current (AC), or direct-current (DC) electric motors are employed. AC inductions motors can draw power directly from the grid. Brushed DC motors use a configuration of wound wire coils (armature), which act as a two-pole electromagnet. The directionality of the current is reversed by a mechanical rotary switch (commutator). Brushed DC motors are offered at low cost with simple and inexpensive controllers and are ideal for extreme operating environments. A draw back are the wear-prone brushes and the need of replacement to extend service life.

In contrast, brushless (BL) motors are equipped with permanent magnets at the external rotor. Furthermore, brushless DC motors (BLDC) utilize three phases of driving coils and sensors track the rotor position. They need less overall maintenance due to lack of brushes. BLDC motors are offered in reduced size with much better thermal characteristics, lower electric noise generation and higher speed range, which is beneficial in stowing conditions. The high-end solution motors for trackers are intelligent BLDC motors with embedded control electronic units. Arctech, Array and Nextracker have sent data about HSAT products equipped with BLDC motors for our survey.

Sometimes hydraulic motor types are employed, where a fluid is used to move the actuator, such as a hydraulic cylinder. Hydraulic systems are useful when load requirements change rapidly. The DC motors can be powered independently with extra PV modules and battery storage as backup. Such self-powered systems are offered by the majority of companies listed in our survey – Arctech, Axial, Clenergy FTC, GameChange, Nexans, Nextracker, PVH, Schletter, Soltec, Soltigua, STI and TrinaTrackers.

Slew drives, a gearbox stage that is specifically designed to handle radial or axial loads while providing rotational output torque, can also withstand overhung or moment loads. Slew drives for azimuthal tracking consist of a metal-ball bearing, worm-gear mechanism, rubber seals and a sturdy housing to protect the drive from the environment. Worm-gear slew drives for solar trackers come often with a reverse self-locking mechanism, which locks a module row automatically when it does not move and thus makes it suitable for installations in locations with high wind speeds. Slew drives are used in many applications across the industry, when strength and precession are required, as they enlarge the power of the motor into a controlled, high torqued output.

Linear actuators are used for the vertical elevation adjustment of solar trackers.In case of independent-row architecture, each tracker is independently actuated and controlled, while in dual- or multi-row HSAT systems two or more trackers are simultaneously driven with a single actuation system. The majority of companies participating in TaiyangNews survey offer independent-row HSATs (Arctech, Array, Ideematec, FTC, GameChange, Grace Solar, Mounting Systems, Nexans, Nextracker, Schletter, Soltec); while a few manufacturers sell both single-row and dual-row systems models (like TrinaTracker, PVH, Axial).

The text is an excerpt from the TaiyangNews Report Solar Trackers: First Comprehensive Technology Overview with Product Specs For A Key Component With Increasing Share In Utility-Scale Solar Power Plants – The TaiyangNews Market Survey Report can be downloaded for free here.

A comprehensive overview on Solar Trackers was provided by Dr Olga Papathanasiou during the TaiyangNews Solar Tracker Conference; the recording can be viewed here.

.png?w=50&fm=png)