Photovoltaics is a young technology. The book shows how the terrestrial solar industry had its origins in the 1973 OPEC oil crisis. In today’s solar boom it is hard to imagine or remember the resistance faced by the early industry. PV pioneers had to combat widespread scepticism that solar cells even worked; costs were astronomically high; and the burgeoning semiconductor sector was sucking up the best research brains.

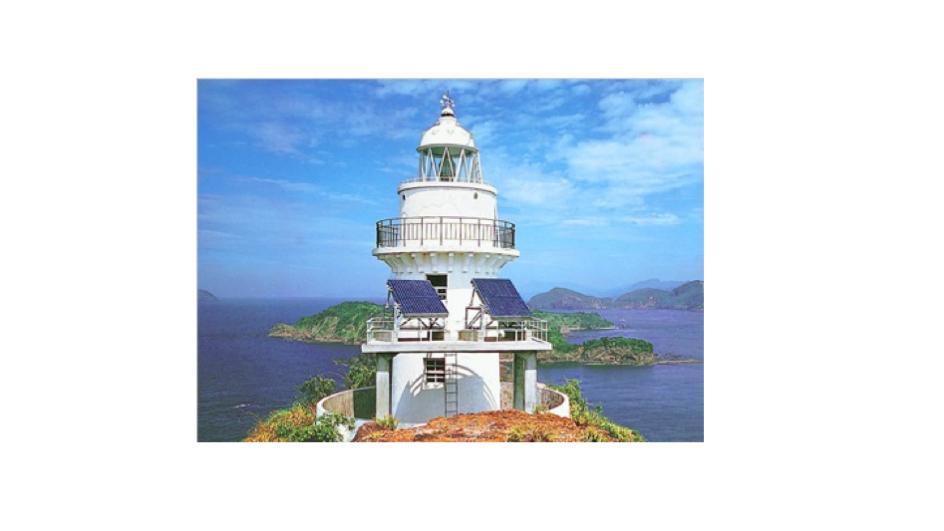

Nonetheless, the oil crisis had created a demand for new energy sources and a handful of luminaries saw solar power as a promising option. There had been limited earlier PV activity in the space industry – notably by Spectrolab, the Hughes Aircraft subsidiary – and by leading electronics companies like Philips and Sharp.

But the prime movers in the early growth of photovoltaics were not the multinationals, but new specialist companies mainly in the USA, notably Elliot Berman’s Solar Power Corporation; Joseph Lindmayer and Peter Varadi’s Solarex; and Bill Yerkes’ company, which became Arco Solar. The earliest volume-produced solar cells used round wafers of monocrystalline silicon. In due course, the drive to reduce costs led to the development of cast polycrystalline silicon, pioneered by Solarex amongst others. But thin-film solar cells were viewed as the obvious route to significant cost reductions, and most major PV companies had a thin film research activity.

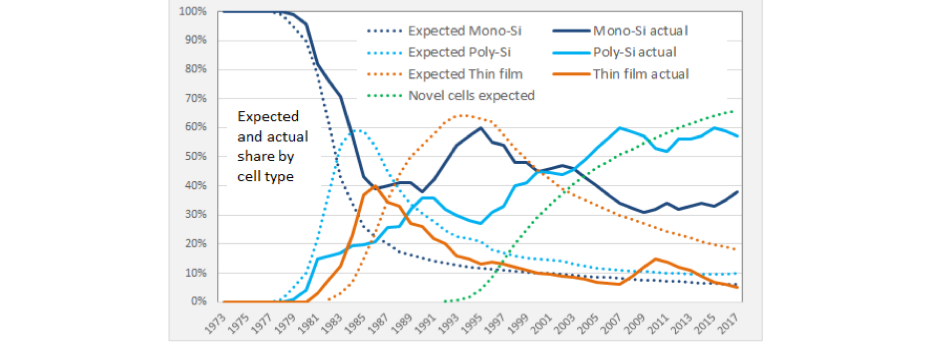

The widely held view was that there would be a progression between these technologies as cost reductions were delivered. It was assumed that polycrystalline silicon would progressively take over the major market share from monocrystalline; that thin films would then dominate; probably to be replaced in turn by novel technologies such as heterojunctions and organic solar cells. Up until the mid-80s, this prediction looked good. However, crystalline silicon technologies refused to concede their market dominance. Their continuing prevalence today would come as a surprise to most pundits in the early PV industry.

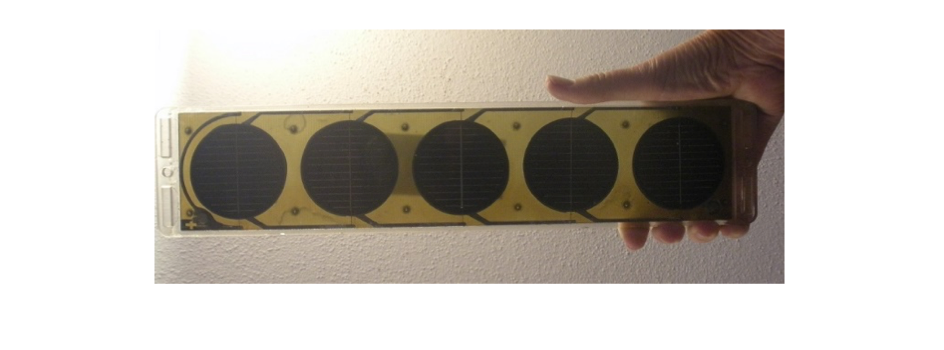

Early solar modules were rather rudimentary. The first volume produced panel by Solar Power Corporation mounted five 2-inch round silicon solar cells on a fibreglass printed circuit board, which was then encapsulated in silicone rubber behind a polycarbonate front cover. More robust and inexpensive designs soon evolved, notably lamination with toughened glass, first pioneered by Spectrolab and Arco solar. This type of aluminium-framed laminated module remains the most common product in the market today.

While there has been dramatic progress in manufacturing and process techniques, it is astonishing how little the core technology has really changed over the last forty years, apart from steady improvements in efficiency. But while the cells and modules remain remarkably similar to what we were using back in the 1980s, the economics and the markets have changed beyond all recognition. And we will return to that in the next two articles.

The content is from Philip Wolfe’s book on the first quarter century of the terrestrial PV sector ‘The Solar Generation: Childhood and adolescence of terrestrial photovoltaics’, which was published by Wiley and IEEE earlier this summer.