- Meyer Burger says it is temporarily lowering its production output at Freiberg location till the end of January 2022

- Cites above-average sick leave being taken by its employees and official quarantine due to COVID-19 as reasons

- Management is hopeful of better time in 2022 but has informed its customers of its decision to increase prices next year

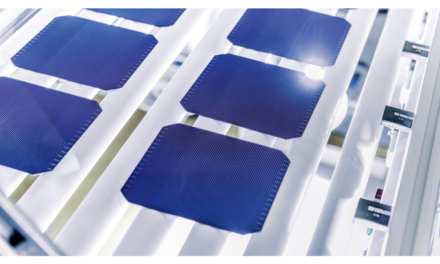

Meyer Burger Technology AG is adjusting its solar module production plans at Freiberg in Germany’s Saxony as it temporarily restricts the manufacturing facility. It cites the reason as above-average sick leave being taken by its staff due to COVID-19 resurgence in the country.

The company explained, “The dynamic development of the corona pandemic in Germany with a sharp rise in the number of infections is also causing the Meyer Burger workforce to have an above-average number of absenteeism due to illness and officially ordered quarantine.” Notably, Germany is imposing major restrictions on people who are not vaccinated as yet.

While the 400 MW solar module fab is being ramped up, it is forced to temporarily operate only 1 of the 2 production lines on location which is likely to lower its production volume that’s likely to last till the end of January 2022.

“Due to the work required in parallel to the production operation for the planned expansion of the existing production facility from 0.4 GW to 1 GW, the production output at the Freiberg location was and will also be limited at times. The production restrictions will have a negative impact on sales in 2021,” admitted the management.

However, it remains confident of achieving guidance for 2023 and says the further announced capacity expansion at the Freiberg, Thalheim (Bitterfeld-Wolfen) and USA locations will proceed as planned as these locations are not affected by the pandemic situation (see Meyer Burger Raises Capital To Expand Production Capacity).

This situation for Meyer Burger arises at a time when the global solar supply chain is dealing with logistical and freight challenges which it admitted to experiencing in August 2021 (see Europe PV News Snippets: Meyer Burger, Endesa, Trianel).

However, the company is quite upbeat about things getting better in 2022. It sees order intake developing positively leading to its order backlog growing. The cell and module maker says to deal with the general cost development and like its competitors, the company has increased prices from 2022 and informed customers accordingly.