- The 6th edition of ITRPV sees a lion’s share of 80% being AR coated glass all along 10 years from now

- AR coatings can improve module performance by up to 2%

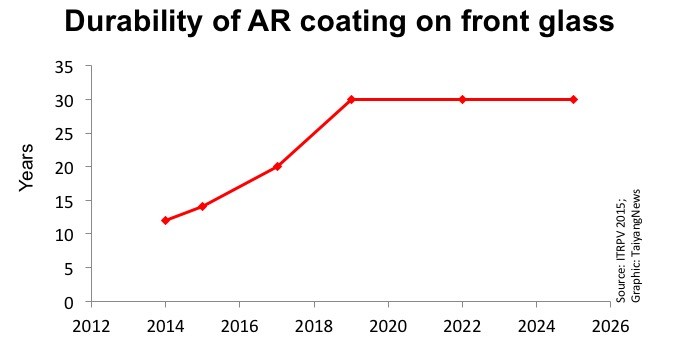

- ITRPV expresses concerns about the durability of AR coatings, which currently last only half of the module’s service life but would be at par in 5 years

- Polymer covers are expected to reach a 10% share in 2019, while plain glass would extinguish from the market in the next 10 years

- No updates are available for developments in glass thickness, but the 2014 roadmap expected 2.5 mm glass would enter mass production in 2016

Module making is a process, in which the manufacturing costs are mainly governed by materials costs. There are two ways to go down on materials costs – either reduce the consumption or contribute to the performance improvement of the PV substrate. The front cover glass is one consumable that has the potential to contribute to cost reduction in either ways. The International Technology Roadmap for Photovoltaic´s (ITRPV) 6th edition’s glass chapter looks at this topic, which is very different from the aspects that were covered in the prior 2014 study. A bless in disguise – though a status update on previously covered topics is missing, the new pieces provide a fairly good estimate on technology trends of the front cover glass, while last year’s findings still hold good.

Being more transparent

The contribution of glass towards module performance improvement deals with reducing optical losses – lowering absorption as well as reflection. Front cover glass coated with antireflective (AR) coatings or a structured surface improves transmission of the glass. Optimization of these coatings to improve the transmission over the relevant range of the solar spectrum, especially to match the absorption band of encapsulation materials and the solar cell can result in up to 2% performance boost in module performance, reported the 5th edition of the roadmap in 2014. The 2014 study also depicted that glass transparency in general would increase linearly from 93.5% in 2013 to 95% in 2016. Only a marginal improvement is forecasted for the next 8 years, reaching 95.5% by 2024.

AR coated glass dominates today and tomorrow

The 2015 roadmap builds on the previous year’s findings and focuses on the commercial aspects of glass. According to the 6th edition, the use of AR coatings on front glass has become common and remains dominant. It is now enjoying a lion’s share of more than 80% of the glass used for solar module manufacturing, and it is expected to remain nearly at the same level for the next 10 years. Plain glass is expected to loose shares consistently from the current level of about 18% and will extinguish from the market completely by 2025. The polymer-based front covering material is expected to gain some share from this fall. With a low single digit presence today, polymer glass is expected to attain a 10% share in 2019. The increments in subsequent years are just marginal. Deeply structured glass will be around in the market, but is not expected by ITRPV to gain a noticeable presence in next decade.

Strong dominance: AR coated glass will continue to dominate with a consistent 80% market share, according to the 6th ITRPV roadmap.

The 2015 roadmap also evaluates the durability aspects of AR coatings. “Not all AR coatings in the market” have a durability matching a solar module’s lifespan, ITRPV warns. Nevertheless, the roadmap is optimistic that the average effective tenure of AR coatings, which is currently a little less than 15 years, will be gradually doubled to 30 years by 2019, which means that within only 5 years it would be more than today’s typical module performance warranty of 25 years.

Forever coated: While ITRPV 2015 estimates that the present durability of AR coatings is about 15 years, the lifespan of these coatings is expected to double by 2019, which would then exceed the module’s typical performance warranties of 25 years.

However, the 2015 roadmap has missed to provide an update on material costs, which is the ongoing effort to reduce the glass thickness. According to previous year’s report, 3.2 mm was the standard glass thickness, which still holds good. The obvious way to reduce the glass consumption is to employ thin sheets. To what extent? According to ITRPV, using 2 mm glass is possible, but to circumvent the mechanical stability issues, a glass-glass configuration would be inevitable. The 2014 roadmap underscored the significant progress made by the industry in cost-effectively producing the hardened glass of thickness even below 2.5 mm and successfully commercializing it. Such glass was expected to be in mass production in 2016. Indeed, some module makers are evaluating 2.5 mm glass, but mostly for glass-glass module configurations.

Such thin glass may also compete with backsheets in terms of price in the future. However, another big benefit of the glass-glass module concept is when it is coupled with advanced cell concepts such as bi-facial cells. Then it also adds significantly to the performance boost. That means the glass – be it on the front side or both sides – has potential to reduce the costs directly as well as indirectly by contributing to the performance improvement of PV module.