- LED-based light engines are becoming increasingly popular in solar cell testers, due to their longer lifespan and greater flexibility

- The ability to test high capacitance cells at high speed is becoming increasingly important, as new cell technologies such as HJT and TOPCon gain market share

- Several companies are developing solutions to test busbar-less cells, which are becoming more popular in the solar industry due to their improved efficiency and reduced cost

The cell testers sitting at the end of cell production lines are similar to teller machines which count the number of watts a cell can produce, and this data can then be used to estimate the revenue it can generate. After all, PV products are sold on a per-watt basis. The main purpose of the cell testers is to simulate sunlight indoors and conduct IV testing at standard test conditions (STC).

As to the recent developments, IV characterization of high capacitance cells such as HJT and TOPCon at high speed is gaining importance. The topic was extensively discussed by Sascha Esefelder, director of product development at Wavelabs, in his presentation titled “High Throughput IVClassification Of High Efficiency Silicon Solar Cells,” at the TaiyangNews Virtual Conference on Solar Cell Production Equipment & Processing Materials, held on February 28, 2023 (see recording here). While he took HJT as the cell technology of reference, as was fully described in the HJT report, the findings are equally applicable to TOPCon.

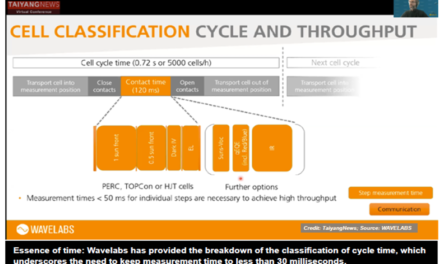

Esefelder emphasized that reaching a throughput of 5,000 wafers per hour requires a cycle time of 0.72 seconds that in turn puts a limit on measurement time at less than 50 ms. While PERC supports a 20-ms measuring time, even 250 ms is already too fast for cell architectures with high internal cell capacitance. To bring the IV characterization pace on par with the industry level, Wavelabs developed an algorithm called RapidWAVE that reduces measurement times to less than 30 ms. The company’s SINUS-300 testing tool platform not only features the function but also enables measuring times spanning a few seconds to cross-check the accuracy of the fast measurement on the floor. halm calls this method hysteresis and has been offering the measurement technique integrated into its cell testers already for several years. The testers from ASYS and Sinton are also capable of supporting the measurement of high capacitance cells in a short measurement time. Within the cell tester segment, the key highlight from ASYS is that it is working on a solution to contact busbar-less cells.

As to the listed specifications, halm’s data is the most elaborate. It is listing only one model called cetisPV-IUCT-3600-BF. The product features 2 light sources based on a xenon lamp, and with an illumination intensity range of 20 to 110 W/m2 and an A+A+A+ class light source. In terms of the tester’s ability to support advanced metallization schemes, halm said that for inline production systems, standard cell contacting systems based on spring-assisted contacting pins / probes are typically supplied by the automation vendor. For special printing layouts such as busbar-less or MBB cells, however, halm has developed a universal contacting solution. The solution is based on contact bars with a hook-like structural design and a soldered ribbon at the bottom as a continuous contacting line. halm has limited its scope of supply to the H contact bars, which have to be integrated into the contacting system by the automation vendor. The tool is integrated with the so-called advanced hysteresis method, allowing reliable measurement of any known silicon-based technology, including TOPCon and HJT. In addition, the tool can also perform SunsVoc, 2-diode analysis, infrared imaging, 2-wavelength spectral response measurement, grid resistance measurement, and EL imaging with automated image evaluation. It has a rated throughput of 4,000 cells per hour with standard system configuration, while higher throughputs are possible as well with an additional flash power booster.

ASYS has provided data for one tool, called AIRON CT, which has a light engine developed by Botest, a subsidiary of ASYS. The AAA-class LED flasher has 3 quadrant electronic load with illumination intensity of 10 to 120 mW/cm2. The tester’s light pulse duration can be set from 5 to 1,000 ms. The IV tester features a patented contacting system that can be adapted to different cell layouts, bifacial and busbar-less measurement for example, according to solar sales director Matthias Drews. In line with current market requirements, the company has updated the tester to be compatible with larger wafers. The tester can perform hysteresis and dark measurement as part of the advanced characterization package, while EL, IR and grid resistance are among the additional characterization methods the tool can take up. For bifacial, while ASYS is providing single-side measurement as standard, it is also open to integrating a second light source on special request. Being a supplier of the complete backend line, ASYS is also offering the tester integrated into the sorter that comes with either manual or automatic loading/ unloading of bins.

We have data for 2 tester modules from Wavelabs, and both are based on an LED light engine. While the SINUS-70 is a lab-scale system with 51 x 51 mm illumination area, the SINUS-300 is a commercial tool designed for production. It has 2 light sources to support the bifacial measurement in an illumination area of 240 x 240 mm that can easily accommodate G12 wafers. This light generator can work in both steady state as well as flasher modes and qualifies for an A++AA++ rating. It illuminates solar cells with an intensity of 10 to 160 mW/cm2. The tester is designed to collect 4,000 data points to generate an IV curve in 20 to 205 ms. It has a rated average throughput of 4,000 cells per hour.

Sinton Instruments has provided data for 2 models, FCT-750 and FCT-650. Both come with very similar specifications: they are based on a xenon flasher with a lifespan of 10,000,000 flashes and a class A+A+A+ light generator, and illuminate the sample with an intensity ranging from 1 to 120 mW/cm2 on a maximum illumination area of 230 mm x 230 mm. The devices support both pulsed and quasi-steady-state illumination methods. The testers feature patented Voltage Modulation to neutralize the capacitive effects in IV measurements. In addition to IV testing, these 2 products can also undertake EL, PL and hotspot tests, while accomplishing advanced characterization at the same time, including substrate doping, power loss analysis, SunsVoc, and minority carrier lifetime curves. Both tools have the same rated average throughput of 3,600 wafers per hour. While the 2 devices have been on offer for many years, the FCT-750 is somewhat younger, launched in 2015; the FCT-650 was already introduced in 2008.

The article is an excerpt from the TaiyangNews Market Survey on Solar Cell Production Equipment 2023, which also includes detailed product specs and can be downloaded for free here.