- ARENA has awarded AUD 11 million to solar cell metallization technology company SunDrive

- By replacing expensive silver with abundantly available copper, SunDrive technology has the potential to bring down the cost of solar, it added

- The company will use the funding to expand its current prototype line to over 100 MW/year capacity for commercial production

The Australian Renewable Energy Agency (ARENA) has tipped AUD 11 million ($7 million) in SunDrive to enable the company bring its copper-based solar cell metallization technology to commercialization. SunDrive also separately announced the opening of its solar manufacturing pilot production and commercialization facility in Kurnell, New South Wales.

Currently, SunDrive operates a 1.5 MW/year prototype line, which it aims to expand to a commercial capacity of more than 100 MW/year. Its Kurnell fab was inaugurated by Australian Prime Minister Anthony Albanese.

What makes it ‘novel’ is the replacement of silver in the metallization paste with copper that’s abundantly and cheaply available, hence has the potential to bring down the cost of overall solar systems. In comparison, silver accounts for close to half the cost of covering a bare silicon wafer into a finished solar cell.

According to ARENA, SunDrive wants to produce one among the world’s most advanced solar modules at an installed price that’s 20% to 30% cheaper than the other high efficiency solar modules in the market.

“Today only 1 per cent of the world’s energy comes from solar and current technology is already at its limit in terms of cost efficiency and material scalability, and the use of silver is behind all three of these,” said SunDrive Co-Founder and CEO Vince Allen. “With SunDrive’s breakthrough copper technology, these roadblocks can be overcome unlocking a new generation of solar technology.”

On behalf of the Australian government, ARENA is supporting endeavors to ensure ultra low-cost solar for the country with an aim to achieve 30% module efficiency for an installed cost of $0.30/W by 2030, dubbed the 30-30-30 vision.

ARENA says SunDrive’s technology can achieve cost-competitive manufacturing of 30% efficient modules through its low-cost copper metallization technology. It noted that the company has already created the world’s most efficient commercial-sized solar cell. With China’s Maxwell, SunDrive announced silver-free heterojunction cell efficiency of 26.41% in September 2022 (see Impressive 26.41% HJT Solar Cell Efficiency).

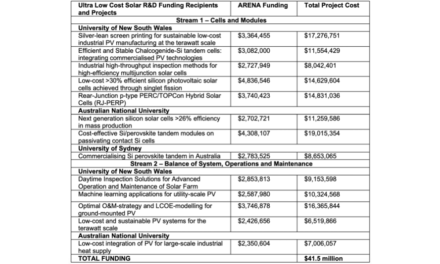

This is SunDrive’s 2nd ARENA funding as it previously secured AUD 3 million from the government agency for its 1.5 MW/year prototype facility (see Australia Funds 13 Projects To Support Low Cost Solar Research).

Recently, in TaiyangNews Virtual Conference on Reliable PV Module Design, participants from leading industry players stressed on optimizing cell metallization paste to deal with corrosion issues of aluminum in silver/aluminum paste (see TaiyangNews Reliable PV Module Design Conference).