- Fraunhofer ISE is working on a spin-off called PV2plus to replace the use of silver with copper in perovskite cell production

- The planned spin-off is being prepped to commercialize the technology as a turnkey process for solar cell makers

- Together the use of copper with perovskite offers a low cost approach for TW scale solar cell production

- Researchers are still working on optimizing PVD metal coating on glass to prevent delamination in the final etch-back procedure

German research institute Fraunhofer ISE is working on a technology to use copper plating to develop environment friendly high performance silicon solar cells without the use of rare materials as silver, which holds the potential to bring down total production cost for the industry. To commercialize this technology as a turnkey process for solar cell makers, it is working to spin-off a company called PV2plus.

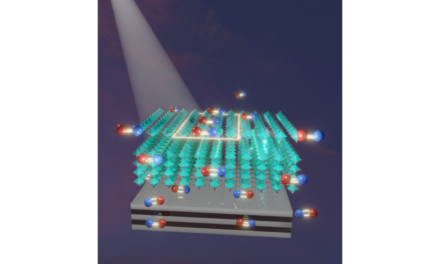

A study by the team on this technology was recently published in the scientific journal Solar RRL under the title Electroplated Copper Metal Contacts on Perovskite Solar Cells.

Through this research, they demonstrate copper contacts can be electroplated on perovskite solar cells (PSC) using aluminum atomic layer deposited (ALD) Al2O3 masking layer on ITO, instead of a polymer layer—building a case for ‘low cost, low carbon footprint approaches for terawatt scale solar cell production’.

Researchers noted equal to 11% photoconversion efficiency after manufacturing the Cu contacts, which gives them the confidence that PSCs can survive the wet chemical plating process.

Going forward, the team believes there is a need to work on optimizing PVD metal coating on glass to prevent delamination in the final etch-back procedure. Fraunhofer ISE said its work on large-area tandem devices is ongoing to improve the cell’s FF with a low-resistivity-plated Cu grid.

The reason behind this research is concern regarding availability of raw material supply including silver as the PV industry grows towards a TW scale. “In this article, we show that PSC survives a plating process, opening the perspective to combine the two promising concepts of Cu plating and perovskite silicon tandems,” state the researchers.

The planned Fraunhofer ISE spin-off PV2plus received an award on World Recycling Day on March 18, 2021 for its technology of substituting silver with copper in the production of silicon heterojunction (HJT) solar cells, which makes it easier to be recycled.

Another Fraunhofer ISE spin-off HighLine Technology GmbH is working on commercializing sustainable cell production by introducing a contactless multi-nozzle dispensing printing process to apply front metal contacts onto solar cells (see Fraunhofer ISE Spin-Off For Solar Cell Production).