- German quality and testing company PI Berlin undertook a study with the help of the Indian government, agencies and KfW to assess India’s PV market and examine the risks facing projects in the country

- Six solar power projects were identified and studied between July 3 and July 14, 2017

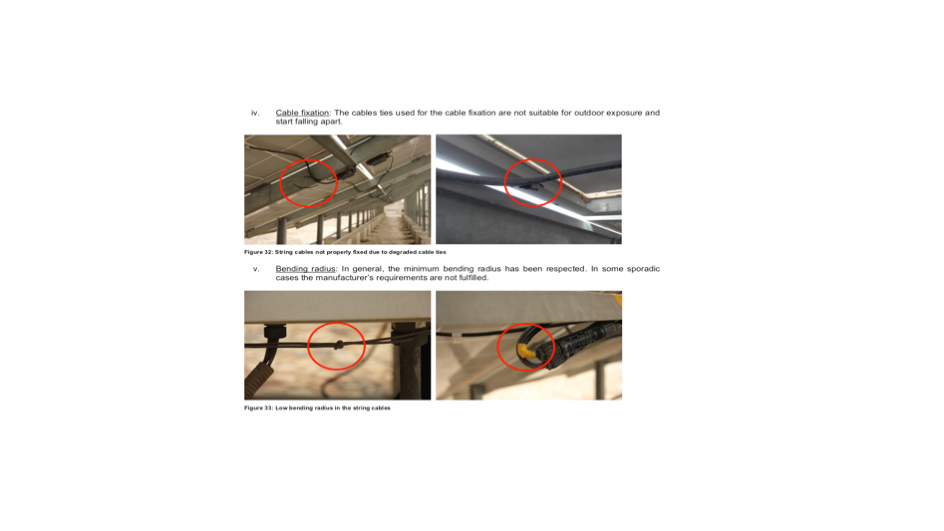

- According to the assessment, major climatic concerns, poor installation and lack of maintenance are the main reasons that adversely impact investments

- With pricing pressure, manufacturers sometimes compromise on quality of modules that are frequently mishandled during transportation, installation and maintenance, which leads to cell cracks

- EPC and O&M contracts need to be clear and not vaguely worded

PV power plants and equipment testing institute PI Berlin calls the Indian solar market a double-edged sword. In its Pilot Study on Quality Aspects of PV Power Plants in India, PI Berlin conducted with the support of India’s Ministry of New and Renewable Energy (MNRE), Solar Energy Corporation of India (SECI) and National Institute of Solar Energy (NISE), it studied six solar power projects to arrive at this conclusion.

Between July 3 and July 14, 2017, it studied six projects that German Development Bank KfW helped identify. PI Berlin calls the market profitable but risky for project developers and investors in PV. Investment risks due to climate concerns, poor installation and lack of maintenance are on the rise.

“In most regions of the world, PV projects are primarily affected by a few climatic stress factors, such as salt in the air, high UV radiation, high humidity, heat, sand or strong winds. But in several areas of India, PV projects often face a large number of these factors at the same time,” explains Asier Ukar, senior consultant at PI Berlin.

Huge pricing pressure leads to compromises on quality of modules in India. PI Berlin observed faulty electrical joints and delamination that could be avoided before and during module production. Proper handling of modules during transportation, installation and maintenance can help avoid cracked cells, it suggests.

Even EPC and O&M contracts are vaguely worded and lack clarity. PI Berlin, which set up its India office in November 2017, makes the case for regular monitoring of performance and operational data (see PI Berlin Expands To India). It asks for improving predictive maintenance and increase system availability.

“The Indian market is a double-edged sword,” said Ukar. “Although India has excellent levels of solar radiation, investments can be put at risk by climatic factors, inappropriate component selection and poor handling and installation quality,” he added. “In order to obtain the highest possible rates of return from PV projects, steps need to be taken to ensure that high-quality components and the proper assurance processes are put in place,” he recommended.

The study was commissioned by the National Metrology Institute of Germany (Physikalisch-Technische Bundesanstalt–PTB). The Pilot Study on Quality Aspects of PV Power Plants in India is available on the PTB website for download.