- TaiyangNews Solar & Sustainability Virtual Conference was attended by solar players and industry experts

- They related the efforts PV manufacturing industry is making to bring down its carbon footprint in terms of technological changes

- It also helps that regulation and ESG compliance make it necessary for the industry to adopt sustainability as a practice

With its attribute of being a renewable energy power generation source, solar power is inherently sustainable. However, solar modules also happen to be industrial products whose production processes may not always be so. Yet, as technological advancements take place and sustainability has become a global buzzword and governments and investors are increasingly requiring companies to adhere to ESG criteria, the solar PV value chain is getting more conscious of its carbon footprint too.

To discuss what the solar PV industry is doing and should be doing to become truly sustainable, TaiyangNews brought together PV stakeholders from across the globe for our 1st Solar and Sustainability Virtual Conference on March 30, 2023 to take a 360° view on the topic.

Aquila Capital’s Ozer Ergul stressed on collaboration at all levels to ensure transparency across the PV value and supply chain to make solar truly sustainable. (Photo Credit: TaiyangNews)

The keynote speaker for the conference, Ozer Ergul, Chief Procurement Officer of Germany headquartered investment management company Aquila Capital, discussed the sustainable development concepts for solar power plants.

Reflecting on the current challenges faced by the global solar PV supply chain, extending from concentration of raw materials, inflation, high cost of energy to geopolitical pressures, Ergul classified these as volatile, uncertain, complex and ambiguous (VUCA).

Ergul stressed on the PV industry to have traceability and transparency in its supply chains to ensure responsible production, sourcing and stewardship of materials in times of increased focus on sustainable sourcing and production in the solar industry.

His contention is that with the cross-cultural, cross-country, cross-industrial dynamics in the solar industry, there is a need to have more collaboration and transparency across the PV value and supply chain to ensure solar really makes a difference as it is meant to in a world battling climate change.

LONGi will release its Sustainability Strategy in 2023 and will also completely switch to renewable energy use for its Baoshan fab in China. (Photo Credit: TaiyangNews)

Sharing the sustainability strategy of the world’s largest PV company, LONGi Brand GM & Head of Global Marketing Talisman Huo said the world’s largest PV manufacturer is committed to power its global operations with 100% renewable electricity by 2028 and install energy management systems for operational locations by 2025 as part of RE100, while improving energy productivity by 35% as part of EP100. In addition, LONGi, which has also committed to the Science Based Targets Initiative (SBTi), the company has signed up for EV100, committing to installing sufficiencies charging facilities for electric vehicles in the next 10 years for its employees.

LONGi is on track to make its Baoshan fab in China’s Yunnan its 1st zero-carbon factory in 2023 to be powered by 100% renewable energy and also come out with its Sustainability Strategy for 2030 in its upcoming 6th sustainability report.

Explaining the group’s ambition to make clean energy with clean energy or Solar for Solar, Huo said, “In the future, seawater desalination, desert irrigation can be carried out through the large-scale application of photovoltaic power generation when 70% of the Earth’s deserts become oases, all the carbon emissions in human history can be absorbed.”

TÜV SÜD’s Hailiang Xu recommended manufacturers to have their own carbon management system in-house while seeking 3rd party certifications for their sustainability practices. (Photo Credit: TaiyangNews)

TÜV SÜD’s VP Strategy & PV, Hailiang Xu spoke about zero carbon solar for a sustainable world, giving an example of how regulations can help the industry follow sustainable practices. Europe tops the list with its Ecolabelling system, Waste Electrical and Electronic Equipment and its Recycling (WEEE), Restriction of the Use of Hazardous Substances in Electrical and Electronic Equipment (RoHS) directives.

The solar industry will have a big emission contribution going forward as demand for solar increases, and having regulations and ensuing certifications from a 3rd party as TÜV Süd will help Chinese manufacturers expand their reach in such markets.

Nonetheless, Xu believes companies should have their own carbon management system and think how they can reduce their carbon footprint in manufacturing. While big players are already taking determined steps towards it, more and more Chinese module makers are showing interest in similar certifications for their products.

JinkoSolar’s 12 MW recycling production line has a 95% recycling rate of silver, silicon, copper, said Roy Bi. (Photo Credit: TaiyangNews)

Speaking about taking initiative to bring in sustainability into PV manufacturing, JinkoSolar’s Global Product Solution Manager Roy Bi announced that the Chinese company has a 12 MW pilot production line to recycle its solar modules. It takes 8 minutes/pcs module with a 95% recycling rate of silver, silicon, copper.

Bi said the core technology of disassembling is chemical dissolution extraction and pyrolysis technology. It can recycle waste modules to the level of ‘basic element’. The key issue is volume today as very little module waste is available. However, as more modules retire in the years to come, Jinko considers expanding the line further.

Jinko said it has shipped over 150 GW modules, more than any other company. It has committed to have all its operations powered by 100% renewables already in 2025 as part of its RE100 committment.

PV Cycle’s Jan Clyncke said the PV industry should be talking about its inherent sustainable nature since PV products come with long term guarantee. (Photo Credit: TaiyangNews)

The same one on recycling comes from PV Cycle, the European association for voluntary take back and recovering of solar modules. PV Cycle’s Managing Director Jan Clyncke pointed out that since panels are created with an average of 10-year product and over 20-year performance guarantee, these last long. Due to this reason, there is currently hardly any significant volume entering the waste cycle. While this is great in terms of reducing waste and is something the PV industry should be communicating to the world as a mark of its sustainable nature, it means that today’s industrial mass-recycling facilities used for other industries would eat up solar waste instantly, economic operation on solar waste only processing would not be possible.

Technological advancements are taking place at a rapid pace which will also contribute to making the production processes and components most environment friendly in the future.

However, he did add that a lot of times old modules are shipped to regions with no technical or political know-how of managing these. That’s where the PV industry needs to have integrity to not indulge in such acts. At the same time, low-income countries should have PV/electronic waste treatment facilities locally to avoid landfill disposal at end-of-life.

Risen Energy’s Leon Zhuang said HJT modules reduce the use of raw materials while improving reliability. (Photo Credit: TaiyangNews)

Risen Energy’s Global Marketing Director Leon Zhuang delved into commercial low carbon footprint of heterojunction (HJT) modules. Pitting these against the workhorse PERC, Zhuang said that the use of ultra-thin wafer size of 100µm for HJT modules reduces the use of raw materials while improving reliability. The company now aims for 210mm+80µm ultra thin silicon wafer.

High production processes to incorporate busbar technology requires large amounts of energy leading to increased costs and carbon emissions. The goal is to now maintain low temperature in cell manufacturing process while reducing the amount of silver used.

Endurans Solar’s Imco Goudswaard said its HP circular backsheets can be recycled using high efficiency pyrolysis. (Photo Credit: TaiyangNews)

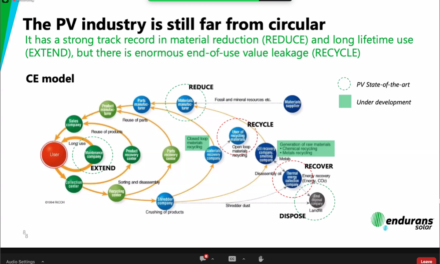

Imco Goudswaard, Commercial Manager and Sustainability Lead at US backsheet company Endurans Solar, was of the view that backsheet material choices made today will have a big impact in 30 years. Traditional backsheets are likely to end up in landfills with a 500 kton/year volume by 2050 without being recycled, but Endurans Solar says its HP circular backsheets can be recycled using high efficiency pyrolysis and reused.

He called HP circular backsheets a ‘sustainable’ solution through the elimination of fluoro-polymers and adhesives and mono-material design.

Cybrid’s Stephen Gong says fluorine-free backsheets can be recycled at the end of its lifecycle. (Photo Credit: TaiyangNews)

In his presentation, Cybrid’s Senior Product Manager Stephen Gong also batted for non-fluoro content backsheets using recyclable materials saying these contribute to lower carbon footprint. In the event of a fire, fluorinated backsheet can produce toxic fumes too. At the same time, fluorine-free backsheet can be recycled at the end of its lifecycle. However, his focus was on PET based products. Gong said interest is quickly increasing, and products are around 20% cheaper than fluoro-coated products.

As Europe continues to focus on sustainability, Gong believes more Chinese companies will be shipping to Europe mindfully especially targeting the distributed PV market.

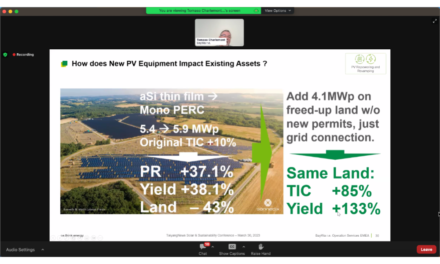

Tomaso Charlemont, Lead Product Manager PV Revamping/Repowering EMEA at BayWa r.e. pointed at revamping/repowering as improving sustainable value and profitability of solar power plants.

Sharing the importance of repowering solar PV systems in the event of module or cell failure, or natural causes as hailstorms, wildfires, Charlemont explained that revamping refers to replacement of defective or underperforming PV plant components. New components have higher efficiencies so will improve yield and allow for better use of land. Such a process will also lower O&M costs.

BayWa’s Tomaso Charlemont reflected on the need and opportunity for revamping/repowering of solar systems. (Photo Credit: TaiyangNews)

Repowering, on the other hand, is a plant redesign that aims to maximize the total system capacity within the limited land area of the original plant. He showed an example where a revamping lead to a 38% yield increase, and installing new modules on the freed space through repowering to a total yield increase of 133% (see slide above).

Since 50% of the modules due to enter recycling still have almost 80% of their original power after 10 years, these can be reused. “Maximizing components’ lifetime increases sustainability, reduces carbon footprint,” explained Charlemont.

Executive Panel

Moderated by TaiyangNews Managing Director Michael Schmela, the executive panelists deliberated on how solar sector can become even more sustainable.

Aquila Capital’s Ozer Ergul was of the view that conforming to ESG guidelines for solar products helps improve not only the sustainability of the product itself but also improves the brand image in the eyes of well-informed customers. It is a great tool to ensure acceptability for the technology.

Endurans Solar’s Imco Goudswaard added that companies should be responsible enough to source, produce and operate sustainably without waiting for government directives. He also was in favor of diversifying the solar supply chain to local markets which will be sustainability in practice as it would bring down huge costs and emissions by cutting down shipping.

JinkoSolar’s Head of Sustainability Development Lin Sun advocated for manufacturers offering better warranties to make their products last long while also training their lens on recycling technologies. Combining solar with other complimtary technologies as storage or hydrogen or wind is also a sustainable practice which should be encouraged. She also recommended governments reduce their lengthy paperwork and legislations for solar to quickly come online.

Agreeing with Sun, BayWa’s Tomaso Charlemont pointed at the socially contributing nature of PV technology as it is paired with agriculture and water bodies in the form of agri-PV and floating solar.