- The benefit of bifacial technology is realized at the system level with improved power yield, while employing larger wafer immediately boosts power rating, and the approach also enables savings in BOM.

- Making rear conver transparent is the key change with bifacial module making; while glass more or less a unanimous choice, reliable transparent backsheet products are also available

- Glass and transparent backsheets with grid enables maintain the power ratings at par to monofacial variants

- M6, M10 and G12 are the current mainstream cells sizes on which of module are typically built on, while it is almost certain that the indsutry is quickly moving away from M6

This article discusses the role of bifacial technology and larger wafers formats in solar modules, following on story discussing the CTM topic, where we provided an overview on how the CTM power ratio can be improved through better light management and reducing resistance losses (see Advanced Module Technologies For Better CTM).

Bifacial and larger wafer formats can be considered as advanced module technologies, though the change does not essentially start at the module level. While these two approaches do demand a change in module making, the benefits are realized at different levels. The benefit of bifacial technology is realized at the system level with improved power yield. Though employing larger wafer immediately boosts power rating, the approach also enables savings in BOM.

Bifacial: Technically speaking, making bifacial, i.e., making a PV device light sensitive on both sides, is more of an effort at the cell level than at the module level. But, every advanced cell technology is naturally bifacial, and tweaking PERC into bifacial is easy. It does, however, require a considerable change in BOM. The first one is to make the rear cover transparent, and glass has naturally been the choice to replace the opaque backsheet. The glass-glass configuration is the key enabler of bifacial technology. There is an industry-wide belief that double-glass modules can last longer, so much so that module makers are confident enough to extend the power warranty to 30 years from 25 years. While 3.2 mm glass is used for the front cover in monofacial modules, using two sheets of glass with 2 mm thickness is the mainstream practice, as efforts are on to reduce thickness without compromising on reliability. A bifacial module requires one more change in BOM when using glass-glass. With respect to PERC bifacial modules, the current practice is to use POE on the rear to provide extra protection from PID.

A transparent backsheet as the rear cover of a bifacial module is an interesting alternative to glass and has its own set of advantages. Modules with transparent polymer rear covers naturally weigh the same as standard modules with opaque backsheet, and do not require any extra care in handling while the manufacturing process remains the same. A few module makers are also offering a 30-year warranty with their bifacial modules with transparent rear cover. For details on transparent backsheets, please refer to our TaiyangNews Market Survey on Backsheets and Encapsulation Materials 2021.

Bifacial technology has one inherent limitation in that it cannibalizes front power due to the loss of sunlight that hits cell gaps. First glass makers, then followed by backsheet makers, devised a workaround where they print a reflective film to fill in the empty spaces, while the areas occupied by the cells remain transparent. This mimics the role of a white backsheet in a standard module, giving the bifacial solar panel the appearance of a monofacial module from both sides. Bifacial technology is a vast subject on its own with developments across the supply and value chain. For more details, please read TaiyangNews’ exclusive report on Bifacial Solar 2021 – Part 1: Cells & Modules.

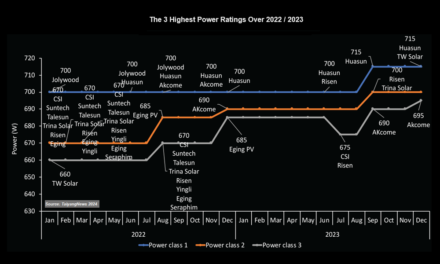

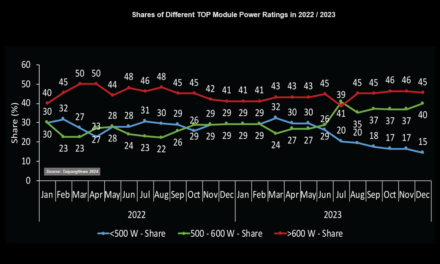

Larger Wafer Formats: Above all, increasing module power by using larger wafers is the most notable technology development in today’s PV domain. For something that could have started as a stunt to be different, this approach spread like wildfire around the end of 2019 to become the most important development over the last 2 years. While there did exist several questions and concerns about it back then, not only have they been perfectly addressed, modules with as high power ratings as 700 W are already commercially available – and are among the . Cutting down on balance of system (BOS) costs is the main motivation behind reaching such high module powers through larger wafers. And the change required for this naturally starts at the combined crystallization and wafering stage. Although there are several wafer sizes out there in the market, M6, M10 and G12 are considered the mainstream sizes today. And while it is almost certain that the mainstream is quickly moving away from M6, its successor remains undecided yet — M10 or G12. Integrated companies are promoting M10, while companies with no strings attached to wafers are jumping directly to G12, and there is already talk of even bigger wafer sizes .

Cell processing is the most impacted from a change in wafer size, but, equipment makers have done a commendable job in this regard. Today’s production tools are capable of handling all mainstream wafer sizes — M6, M10 and G12. Flexibility aside, tool vendors have also readapted their equipment platforms to improve productivity in parallel. The impact of adopting larger wafers in module manufacturing is not as significant as in the upstream processes. But given the final product’s larger dimensions and greater weight, field reliability aspects such as mechanical loading and wind resistance become topics of discussion here. Module makers are aiming at even higher efficiencies by integrating several other advanced module technologies on larger wafer platforms. Understanding the importance of this approach, TaiyangNews has published 2 reports on the subject, the latest is our Very High-Power Solar Modules Report 2021, which can be referred to for further details.

The Text is an excerpt from TaiyangNews’ recent solar module innovations report 2022, which can be downloaded for free here.